RAM'S NEW TWIN-PLATE HIGH PERFORMANCE CLUTCH AND FLYWHEEL ASSEMBLY

Tue, 2009-01-20 10:00

RAM Automotive has announced a new twin-plate high performance clutch and flywheel assembly for the Corvette C6 and C6  ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.

ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.

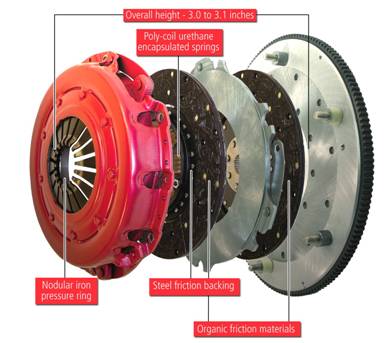

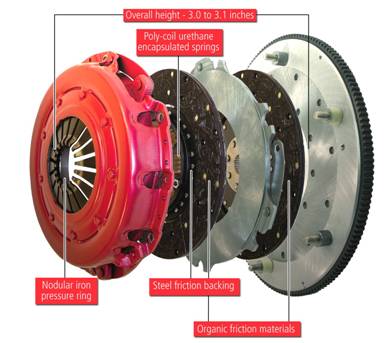

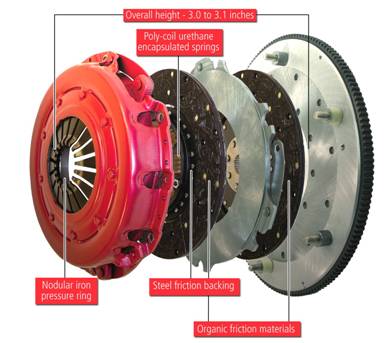

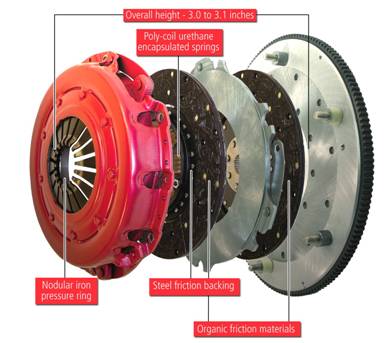

Designed for use in street applications with healthy increases in power (via blowers, turbos, or nitrous), this new clutch arrangement is a true bolt-in twin-plate replacement assembly. Similar in dimensions to the original, its overall height is 3.0 to 3.1 inches (measured from the crankshaft flange to the finger tips of the cover assembly) and its diameter is 10.5 inches.

The DirectFit StreetDual clutch is equipped with a strong, 2400-pound clamp-load diaphragm cover, a nodular pressure ring for strength, and RAM 300 series organic disc friction material. The chief advantage of using organic friction material is its superior holding power and improved driveability without chatter on takeoff. RAM Automotive has announced a new twin-plate high performance clutch and flywheel assembly for the Corvette C6 and C6 ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.

ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.

Designed for use in street applications with healthy increases in power (via blowers, turbos, or nitrous), this new clutch arrangement is a true bolt-in twin-plate replacement assembly. Similar in dimensions to the original, its overall height is 3.0 to 3.1 inches (measured from the crankshaft flange to the finger tips of the cover assembly) and its diameter is 10.5 inches.

The DirectFit StreetDual clutch is equipped with a strong, 2400-pound clamp-load diaphragm cover, a nodular pressure ring for strength, and RAM 300 series organic disc friction material. The chief advantage of using organic friction material is its superior holding power and improved driveability without chatter on takeoff.

The clutch disc springs are also stiffer. By encasing them in urethane, their compression rate increases approximately four times that of an uncoated spring. As a result, this RAM clutch assembly distinguishes itself by not only having the capacity to handle up to 1000 horsepower at the rear wheels but also providing stock driveability.

Since this clutch has to combat greater rotational forces, steel friction backing is added (see accompanying image with call-outs). The facing is riveted steel-to-steel, in contrast with factory non-backed facings.

To complete the assembly, the flywheel is constructed of billet aluminum and contains a ¼-inch thick steel friction insert. This insert (regarded as the thickest in the industry) contributes sufficient mass to dissipate heat, yet maintains a flat friction surface. Thinner inserts are prone to warping.

Luckily for all those seeking technical advice on clutch matters, RAM has an able and experienced team who can provide much valuable, free information. Finally, swift delivery of their top 100 part numbers is executed the same day, if contacted before noon. Three to five days will secure out-of-stock items.

For more information, visit www.ramclutches.com

ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.

ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.Designed for use in street applications with healthy increases in power (via blowers, turbos, or nitrous), this new clutch arrangement is a true bolt-in twin-plate replacement assembly. Similar in dimensions to the original, its overall height is 3.0 to 3.1 inches (measured from the crankshaft flange to the finger tips of the cover assembly) and its diameter is 10.5 inches.

The DirectFit StreetDual clutch is equipped with a strong, 2400-pound clamp-load diaphragm cover, a nodular pressure ring for strength, and RAM 300 series organic disc friction material. The chief advantage of using organic friction material is its superior holding power and improved driveability without chatter on takeoff. RAM Automotive has announced a new twin-plate high performance clutch and flywheel assembly for the Corvette C6 and C6

ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.

ZO6. They have christened it the DirectFit StreetDual and have allocated its part number as 90-2100.Designed for use in street applications with healthy increases in power (via blowers, turbos, or nitrous), this new clutch arrangement is a true bolt-in twin-plate replacement assembly. Similar in dimensions to the original, its overall height is 3.0 to 3.1 inches (measured from the crankshaft flange to the finger tips of the cover assembly) and its diameter is 10.5 inches.

The DirectFit StreetDual clutch is equipped with a strong, 2400-pound clamp-load diaphragm cover, a nodular pressure ring for strength, and RAM 300 series organic disc friction material. The chief advantage of using organic friction material is its superior holding power and improved driveability without chatter on takeoff.

The clutch disc springs are also stiffer. By encasing them in urethane, their compression rate increases approximately four times that of an uncoated spring. As a result, this RAM clutch assembly distinguishes itself by not only having the capacity to handle up to 1000 horsepower at the rear wheels but also providing stock driveability.

Since this clutch has to combat greater rotational forces, steel friction backing is added (see accompanying image with call-outs). The facing is riveted steel-to-steel, in contrast with factory non-backed facings.

To complete the assembly, the flywheel is constructed of billet aluminum and contains a ¼-inch thick steel friction insert. This insert (regarded as the thickest in the industry) contributes sufficient mass to dissipate heat, yet maintains a flat friction surface. Thinner inserts are prone to warping.

Luckily for all those seeking technical advice on clutch matters, RAM has an able and experienced team who can provide much valuable, free information. Finally, swift delivery of their top 100 part numbers is executed the same day, if contacted before noon. Three to five days will secure out-of-stock items.

For more information, visit www.ramclutches.com

Categories: