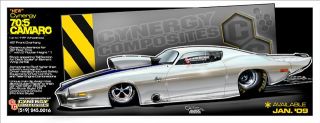

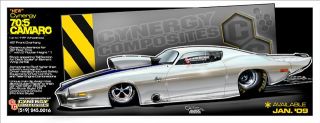

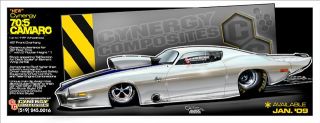

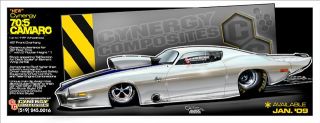

NEW 70.5 PRO MOD CAMARO BODY

Thu, 2008-12-11 11:29

Could a 1970 ½ Camaro body be the next body of choice in Pro Modified?

Cynergy

Composites Inc. in Ontario, Canada recently announced the official

release of this completely original “copyrighted” racing shell. This

body is a fusion of every single racer and builder request over the

past five years submitted to the popular body fabricator.

Cynergy

Composites Inc. in Ontario, Canada recently announced the official

release of this completely original “copyrighted” racing shell. This

body is a fusion of every single racer and builder request over the

past five years submitted to the popular body fabricator.

Could a 1970 ½ Camaro body be the next body of choice in Pro Modified?

Cynergy Composites Inc. in Ontario, Canada recently announced the official release of this completely original “copyrighted” racing shell. This body is a fusion of every single racer and builder request over the past five years submitted to the popular body fabricator.

Cynergy Composites Inc. in Ontario, Canada recently announced the official release of this completely original “copyrighted” racing shell. This body is a fusion of every single racer and builder request over the past five years submitted to the popular body fabricator.

Body features include:

• Generous tire clearance for 36” rear slicks.

• Stock appearing (and Aerodynamic) tail section for deck spoiler or airfoil (element) wing option.

• Unique main clip design that allows builder or racer to finish car with either:

Rockers (Pro Stock Style) or doors to the ground (Pro Mod Style).

• Proportioned and perfectly located inner door boxes that allow doors to swing “in” properly. (No “off-the-wall” hinges where door must swing “out”)

• 45” Front overhang and Front Skirt raised +1” up from rocker.

• Consistent weather-strip recesses in door jams.

• Rear rocker “kick-up” to avoid body rubbing on starting line launch.

• Aerodynamic roof higher than industry average for: driver visibility, taller engine combinations and extra room for improved safety equipment and driver comfort.

Cynergy Composites’ President, Tim Hodgins had a clear vision from the start when he began the overwhelming project in September 2007. Hodgins and good friend (lead hand) Wes Goddard (crew member with Tim on Al Billes’ Funny Car team in the early 1990’s) cut apart a numbers matching 70.5 Camaro Z28 to begin the painstaking task of hand-forming their completely unique “all – steel” body plug creation.

“The steel plug is more work, but the finished product is more precise,” Hodgins said. “The steel gives a stronger base and doesn’t shift or move during the intense molding procedure. Most people wouldn’t believe how we must manipulate this plug to create a perfect set of molds, we appreciate that the plug is a precision piece of equipment.”

Cynergy is committed to delivering bodies in January 2009 so that its customers can be racing by spring.

Cynergy

Composites Inc. in Ontario, Canada recently announced the official

release of this completely original “copyrighted” racing shell. This

body is a fusion of every single racer and builder request over the

past five years submitted to the popular body fabricator.

Cynergy

Composites Inc. in Ontario, Canada recently announced the official

release of this completely original “copyrighted” racing shell. This

body is a fusion of every single racer and builder request over the

past five years submitted to the popular body fabricator.Could a 1970 ½ Camaro body be the next body of choice in Pro Modified?

Cynergy Composites Inc. in Ontario, Canada recently announced the official release of this completely original “copyrighted” racing shell. This body is a fusion of every single racer and builder request over the past five years submitted to the popular body fabricator.

Cynergy Composites Inc. in Ontario, Canada recently announced the official release of this completely original “copyrighted” racing shell. This body is a fusion of every single racer and builder request over the past five years submitted to the popular body fabricator.Body features include:

• Generous tire clearance for 36” rear slicks.

• Stock appearing (and Aerodynamic) tail section for deck spoiler or airfoil (element) wing option.

• Unique main clip design that allows builder or racer to finish car with either:

Rockers (Pro Stock Style) or doors to the ground (Pro Mod Style).

• Proportioned and perfectly located inner door boxes that allow doors to swing “in” properly. (No “off-the-wall” hinges where door must swing “out”)

• 45” Front overhang and Front Skirt raised +1” up from rocker.

• Consistent weather-strip recesses in door jams.

• Rear rocker “kick-up” to avoid body rubbing on starting line launch.

• Aerodynamic roof higher than industry average for: driver visibility, taller engine combinations and extra room for improved safety equipment and driver comfort.

Cynergy Composites’ President, Tim Hodgins had a clear vision from the start when he began the overwhelming project in September 2007. Hodgins and good friend (lead hand) Wes Goddard (crew member with Tim on Al Billes’ Funny Car team in the early 1990’s) cut apart a numbers matching 70.5 Camaro Z28 to begin the painstaking task of hand-forming their completely unique “all – steel” body plug creation.

“The steel plug is more work, but the finished product is more precise,” Hodgins said. “The steel gives a stronger base and doesn’t shift or move during the intense molding procedure. Most people wouldn’t believe how we must manipulate this plug to create a perfect set of molds, we appreciate that the plug is a precision piece of equipment.”

Cynergy is committed to delivering bodies in January 2009 so that its customers can be racing by spring.

Categories: