Rob Wendland, owner of the Star Racer Blower Belt line, has become a pivotal figure in the engine belt industry, creating high-performance products for Top Fuel dragsters, Pro Modified doorslammers, and more. His journey began with a vision to introduce competition into a market dominated by a single manufacturer.

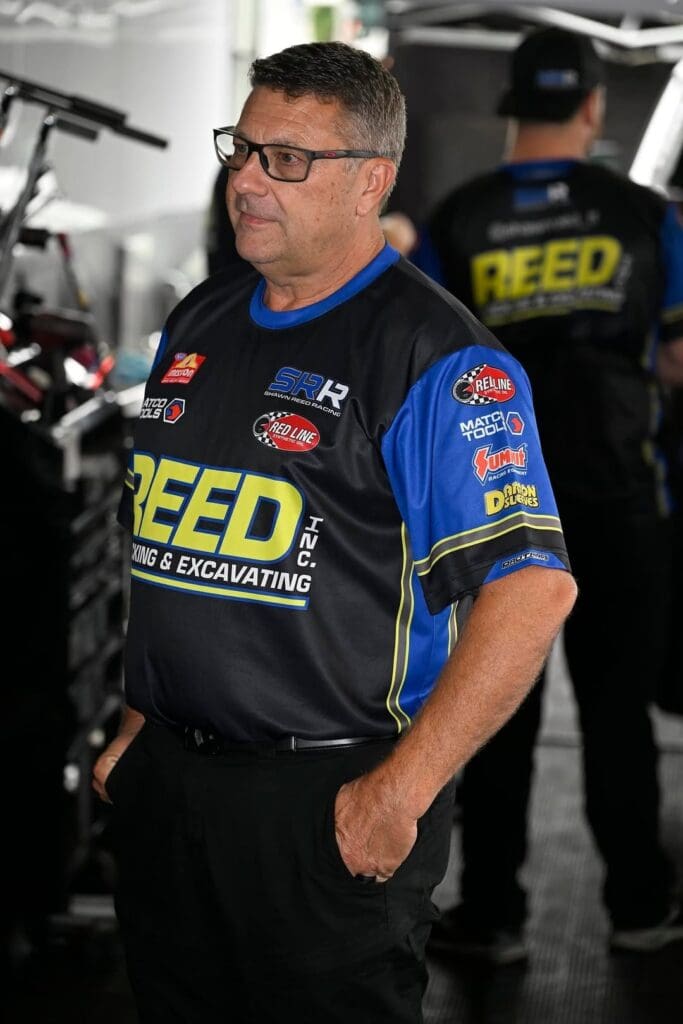

Wendland, a past NHRA U.S. Nationals winning crew chief and current tuner for Top Fuel racer Shawn Reed, made his entry into the supercharger belt business by a chance encounter at the NHRA Route 66 Nationals outside of Chicago.

A friend introduced him to a contact at the MBL plant in Ottawa, Illinois, who suggested that their belt resembled the brand on the Top Fuel dragster Wendland tuned. Over the next three years, Wendland conducted research and built relationships to create a product that would rival existing belts.

“I said, ‘Yeah, people do [need an alternative],’” Wendland recounted, “But having one as strong as the competitor is another thing.”

Wendland was determined to produce a belt that offered not only similarity in design but also superior strength and performance.

Building on his experience as a crew chief, Wendland emphasized that developing a high-quality belt involves more than just manufacturing.

“There was a lot of testing,” Wendland said, noting that the Japanese manufacturers who manufacture his product line take immense pride in their work.

“They don’t want to be embarrassed by any of their products,” Wendland added.

The meticulous nature of the belt-testing process revealed a significant advantage for Wendland’s product. Unlike competitors that used plastic, his belts were made from rubber, which drastically reduced harmonics and engine vibration.

“The reason why they do that is because they didn’t know how to bond carbon and Kevlar to rubber,” Wendland explained.

This technological innovation stemmed from a production error.

“That was actually Mitsuboshi,” Wendland explained. “They had a production mistake and were able, by that mistake, to bond true rubber, NBR rubber to Kevlar and carbon.”

This breakthrough provided a unique characteristic to the Star Racer Belt, making it the only product of its kind available for various applications.

Wendland highlighted how the advantages of his belts translate into performance on the track.

“It goes four or five times more than their competitor does down the track,” he said, emphasizing longevity and performance. The feedback from users is invaluable, as the belts communicate their condition through their wear during runs.

However, the requirements for racing engines, particularly in NASCAR, posed unique challenges. Wendland noted, “In NASCAR, they have to run those motors for three races.” Teams cannot simply switch to new motors without facing penalties, a factor that increases the crucial need for reliable belts.

“I don’t know if a lot of people know this, but a Toyota car was out there, and they actually said that the motor got better after three races,” he continued. The data collected on RPMs and engine revolutions during races further underscores the importance of utilizing high-quality components.

In a highly competitive market, Wendland’s resolve remained grounded in his racing background.

“There was only one supercharger belt on the market at the time,” he recalled. A sense of fairness in pricing motivated him to create a brand that wouldn’t burden small-budget racers. “I was just kind of burned out of that deal, and I thought, man, it’d be nice to have some competition.”

Yet, Wendland’s commitment to affordable pricing is not without its challenges. Over the past three years, he has maintained stable prices amid rising costs, striving to support his fellow racers.

“I’ve taken a lot of price increases over the last three years and never raised the prices,” he said. “But with the tariff increase coming… I just can’t afford to suck that in this time.”

The production of Star Racer Belts is a blend of American ingenuity and Japanese craftsmanship.

“Some of them are made in the USA, and others are made in Japan,” he clarified. “But the material for it is sourced out of Japan, which sees an 8% tariff.” This global approach ensures that the belts are built to the highest standards.

In addition to his work in manufacturing belts, Wendland has explored educational opportunities through YouTube. He has a genuine desire to give back to the racing community by sharing valuable insights and experiences. “If I can help teach another team… that was the real reason why I was doing it,” he explained.

Wendland’s YouTube endeavors began as a way to connect with the broader racing audience. He described attending a seminar organized by Top Alcohol specialist Will Hanna, where he helped educate participants on safety and tuning techniques. “I truly enjoy doing that,” he remarked.

The ability to communicate and share knowledge is vital to Wendland, especially since he believes in fostering a supportive community among racers. “I wish I could afford somebody full-time to follow me around,” he noted, acknowledging that capturing the intricacies of racing could inspire and inform.

As Wendland looks to the future, his ambitions are not limited to financial success or social media fame.

“I really want a championship,” he affirmed, recognizing the balance between business and passion. “It’s not my sole source of income.”

Star Racer Belts stands on the brink of becoming a significant player in the racing industry, providing a competitive option for racers who rely on high-performance belts. Wendland’s dedication to quality and innovation sets him apart in an industry that often struggles with consistency.

In a sector where every detail counts, Wendland’s commitment to excellence underscores the importance of listening to racers’ needs.

“I’ve kept this belt very competitive because I’m a racer, so it’s not my sole source of income,” Wendland said. “Yes, I want Star Racer belts to be healthy and take care of itself, and along those lines, I want it to be a product racers can depend on time and time again.”