Ken Perry, a seasoned businessman, recently shifted gears from a 45-year career to pursue a new challenge in the Pro Modified racing world. Launching Ken Perry’s Xtreme/Arias LLC this season, Perry provides high-performance engines tailored to meet demanding standards.

It was his frustration as a Top Alcohol Dragster racer using previous era engines by others that pushed him towards building a superior piece of equipment.

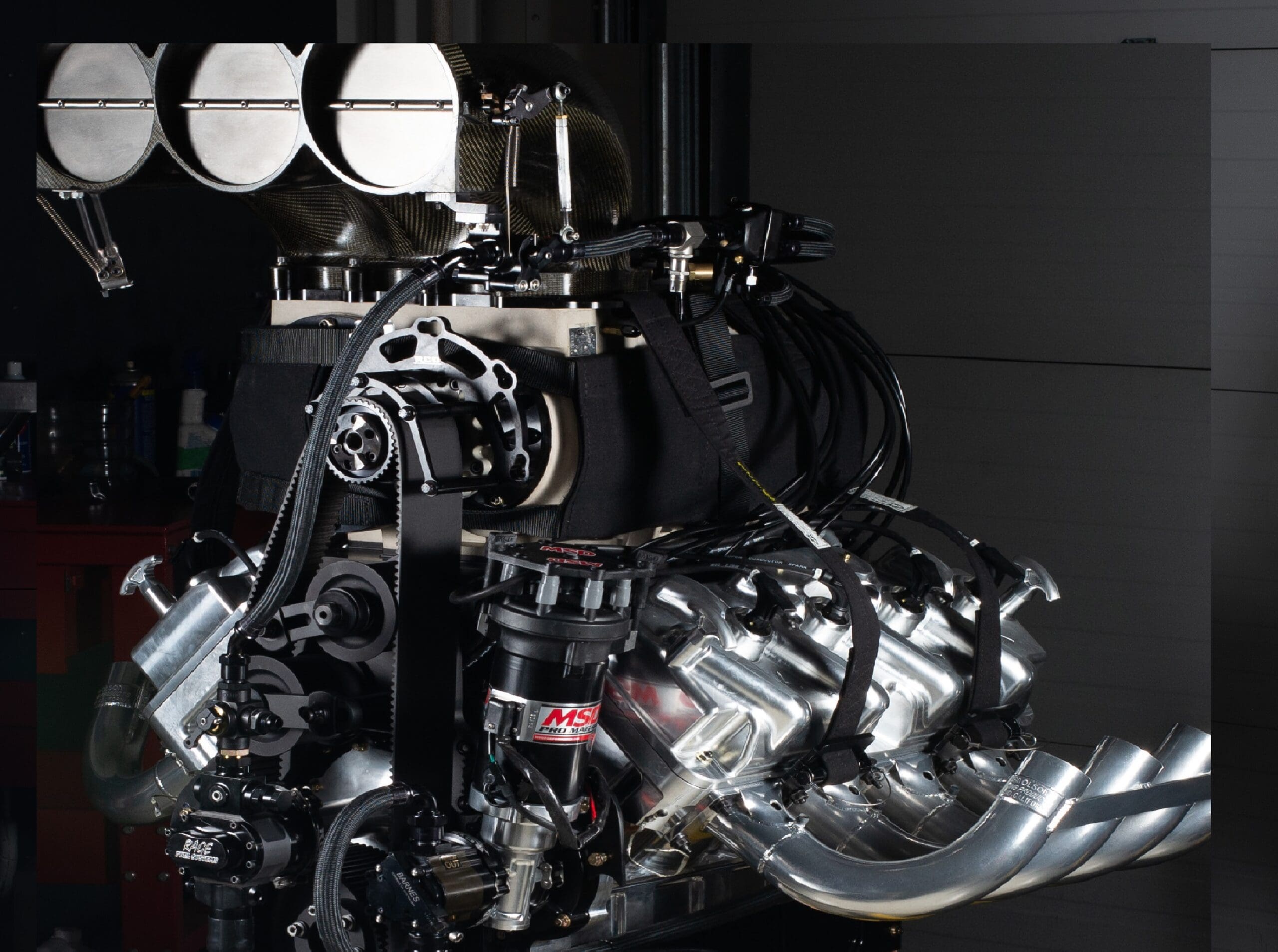

“Well, we were kind of pushed into the position because obviously the people that were trying to make these engines weren’t doing it to our satisfaction,” he explained. This dissatisfaction led the team to redesign the 8.3L Arias engines, focusing on more advanced blocks, improved head flow, and state-of-the-art valve geometry.

The need for enhancement emerged after his years of unsatisfactory engine performance. Perry highlighted the shortcomings of old-style heads, stating that despite having large valves, their design did not allow sufficient airflow, and further issues with valve seats and valve guides moving due to inferior materials, as well as design.

The company introduced advanced materials and manufacturing processes to produce superior components. Perry noted they started using alloy 6013 for cylinder head construction after previous experiences highlighted the lower strength of 6061 material (industry standard). Both the custom valve guides and Moldstar seats, Perry feels, are superior to what others are using.

Their goal extends beyond merely building engines; it’s about ensuring longevity and performance. “The cost of the materials are higher than the competitors, but we’re looking for longevity,” said Perry, emphasizing the increased power demands in today’s racing climate.

Perry also expanded into producing aluminum turbo manifolds, Procharger manifolds, and blower manifolds. We still offer magnesium for its weight advantages. “They’re lighter, but if people are wanting looks the aluminum is real pretty,” he noted.

The Pro Modified market has become a focal point for his company. “We also have an option for magnesium pan rails (again, weight-related),” Perry added, describing how the design allows for quick repairs should a cylinder fail during a race. The pan rail can be replaced, usually without the need for block welding.

Innovation remains at the heart of Ken Perry’s Xtreme/Arias LLC mission.

“We decided to start making our own gears,” Perry added, marking a significant departure from industry norms where few manufacturers do the same. Perry believes the choice reflects a commitment to quality, as evidenced by their long-standing relationship with the established gear maker Donovan. In order to meet the procedures for the gear specifications, a Vargus Tooling solution was implemented for 5 axis machining.

When asked about their competitive strategy, Perry explained, “We just went to the drawing board, reverse-engineered what was there, and then made the changes to that.”

He highlighted advancements in their valve train system, which he said, “Reduces issues of harmonics and combined with a solid rocker plate that is secured with the heads rather than being bolted to the head. There is less chance of the head lifting when detonation occurs that plague other models. This is the stoutest valve train in the industry.”

Ken Perry’s Xtreme Arias LLC team’s ingenuity is evidenced in their design. “By utilizing the 6013 – T651 for the extra strength it minimizes the heads from lifting, therefore, we’ve solved another issue.” Oiling issues were also addressed and have proven successful. To date, Perry said, there have been 2 full typewritten pages of changes and upgrades, and it won’t stop there.

Despite misconceptions about their engine weight, Perry affirmed the efficiency of their product. “Everybody thought the Arias was heavy,” he said, explaining that the scales revealed his engines were actually lighter than their competitors.

The focus on Blown Alcohol and turbocharged engines shows Perry’s broad aspirations. He believes their products are competitive in various racing categories, including Top Alcohol Dragsters and tractor pullers.

“These make more torque than a Hemi,” Perry stated confidently.

In addition to engine design, Perry’s company is committed to innovative manufacturing techniques. “We use HyperMill CAM Software, which was designed specifically for five-axis CNC machining,” he explained, highlighting a distinct choice from many competitors.

Perry believes a few esteemed manufacturers dominate the competitive landscape.

“There’s five of us,” Perry confirmed, naming notable peers like Noonan, BAE, AJPE/Proline. Perry’s efforts to move closer to the competition faced hurdles, recalling frustrating attempts to purchase facilities in South Carolina.

Time and again, Perry emphasized the importance of quality and innovation in their products. His extensive background as a master electrician and certified millwright, etc. enhances his hands-on approach to design and manufacturing.

“I do design. I have guys draw it, and then I’ve got high-end machinists that do the machining,” he explained, illustrating the collaborative effort behind each project. His commitment to high-quality output is also evident in his choice of tools and equipment.

Perry’s transition from a successful electrical and mechanical business to drag racing reflects his passion for the sport. Initially a hobby, racing developed into a full-fledged enterprise.

“Yeah, we had three businesses, and then we walked away from them all,” Perry noted. Aiming for excellence in engineering and manufacturing, he has invested in state-of-the-art equipment to enhance their product quality.

Striving for high performance and durability, Perry’s commitment to the Pro Modified category sets his company apart in racing engines. With innovations that he believes addresses industry weaknesses, Ken Perry’s Xtreme/Arias LLC is poised to make a significant impact on the racing landscape.