Wild Wilfred Boutilier, WW EngineeringHis valve train parts, which are shipped in unmarked boxes, flow from his modest manufacturing facility in north Georgia about fifty miles north of Atlanta. They carry the promise of winning. The shop, which is not open to the public is also unmarked and sits among the evergreen scenery and the burnished magnolia at the end of a neat concrete drive behind a gated entrance. In the shop, customers’ names are rarely mentioned.

Wild Wilfred Boutilier, WW EngineeringHis valve train parts, which are shipped in unmarked boxes, flow from his modest manufacturing facility in north Georgia about fifty miles north of Atlanta. They carry the promise of winning. The shop, which is not open to the public is also unmarked and sits among the evergreen scenery and the burnished magnolia at the end of a neat concrete drive behind a gated entrance. In the shop, customers’ names are rarely mentioned.

Indeed this policy of discretion is understandable as professional racing teams work hard to gain an advantage and it’s in their interests and those who serve them to remain tight-lipped. Racing, particularly the kind where engine power predominates, requires secrecy and Wilfred Boutilier of WW Engineering knows how to play the game.

In nineteen-sixty-five Wild Wilfred Boutilier now 76-years-old left his Nova Scotia homeland, pursuing an ardor for NHRA drag racing. In the nineteen-seventies he competed in Pro Comp Alcohol Funny car, winning at Englishtown in 1974 and again at the Fall Nationals in Seattle, Washington a year later. Boutilier continued racing though not from the confines of a Funny Car. He was the first to create billet heads for Donovan blocks. He also produced them for Lamar Walden’s 409s.

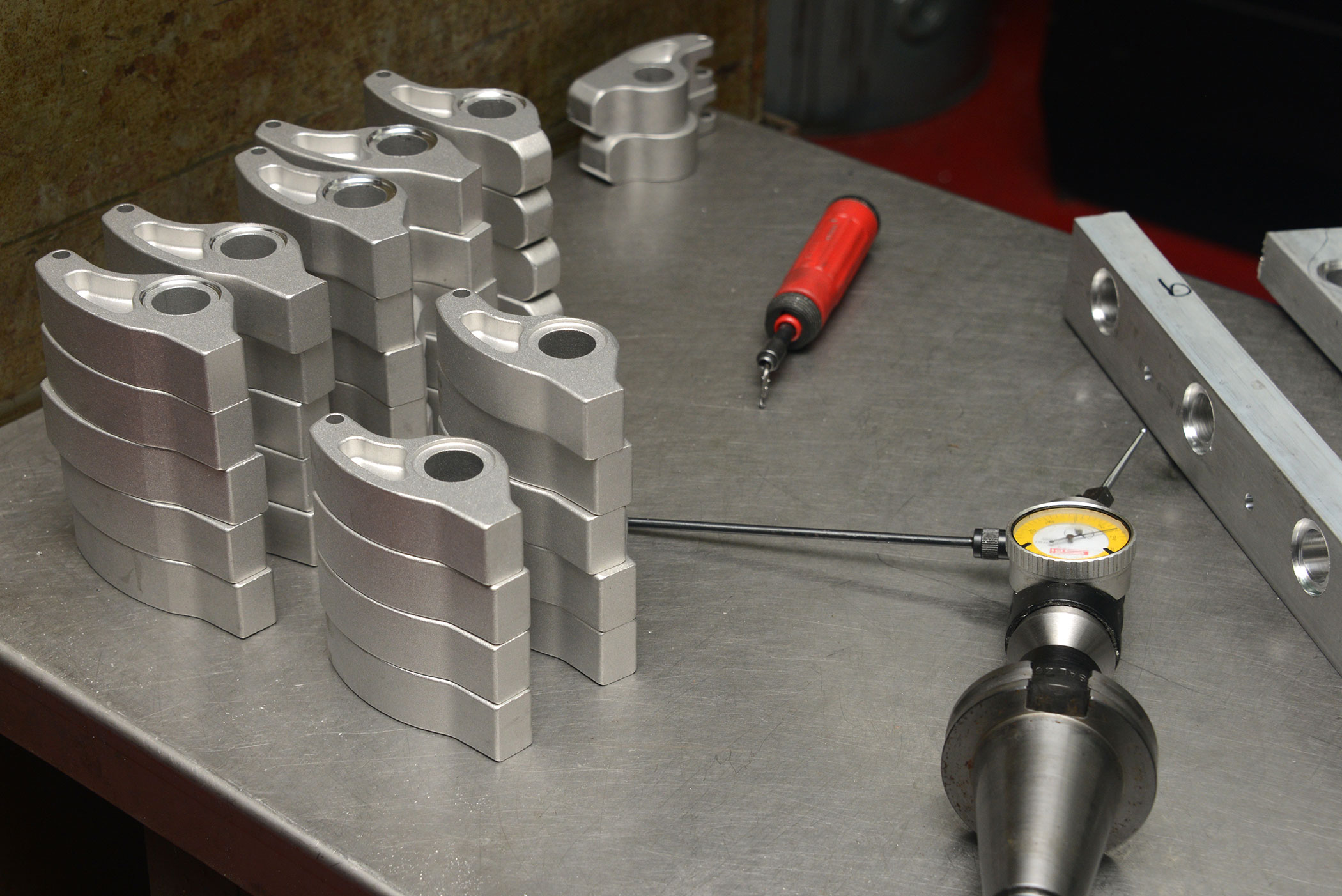

The finest rocker arms you’ve never heard of:

Almost thirty years ago Boutilier began developing competition rocker arms from billet aluminum. Why would he do that? Why would he not use an extrusion where the entire rocker arm is extruded in seconds? For the manufacturer an extrusion eliminates the need to remove wasted material and it is even available with holes for the trunnion and roller tip. “It’s for strength. Because the forces in the rocker arm run longitudinally, from end-to-end,” says Wilfred, “I wanted a similar grain structure in my rocker arm. The grain structure in the extrusion runs perpendicular—it runs across the rocker. Though not quite as strong as a forged item, the billet is usually around ten to fifteen percent stronger than its extruded counterpart.” From each year’s production at WW Engineering, Boutilier can count the number of broken rocker arms on the fingers of one hand.

Now he has announced he is leaving the rural beauty of North Georgia at the end of April to return to his ancient Canadian homeland. Happily, production of his much-prized competition rocker systems will continue discretely, albeit one thousand, seven hundred miles northeast.

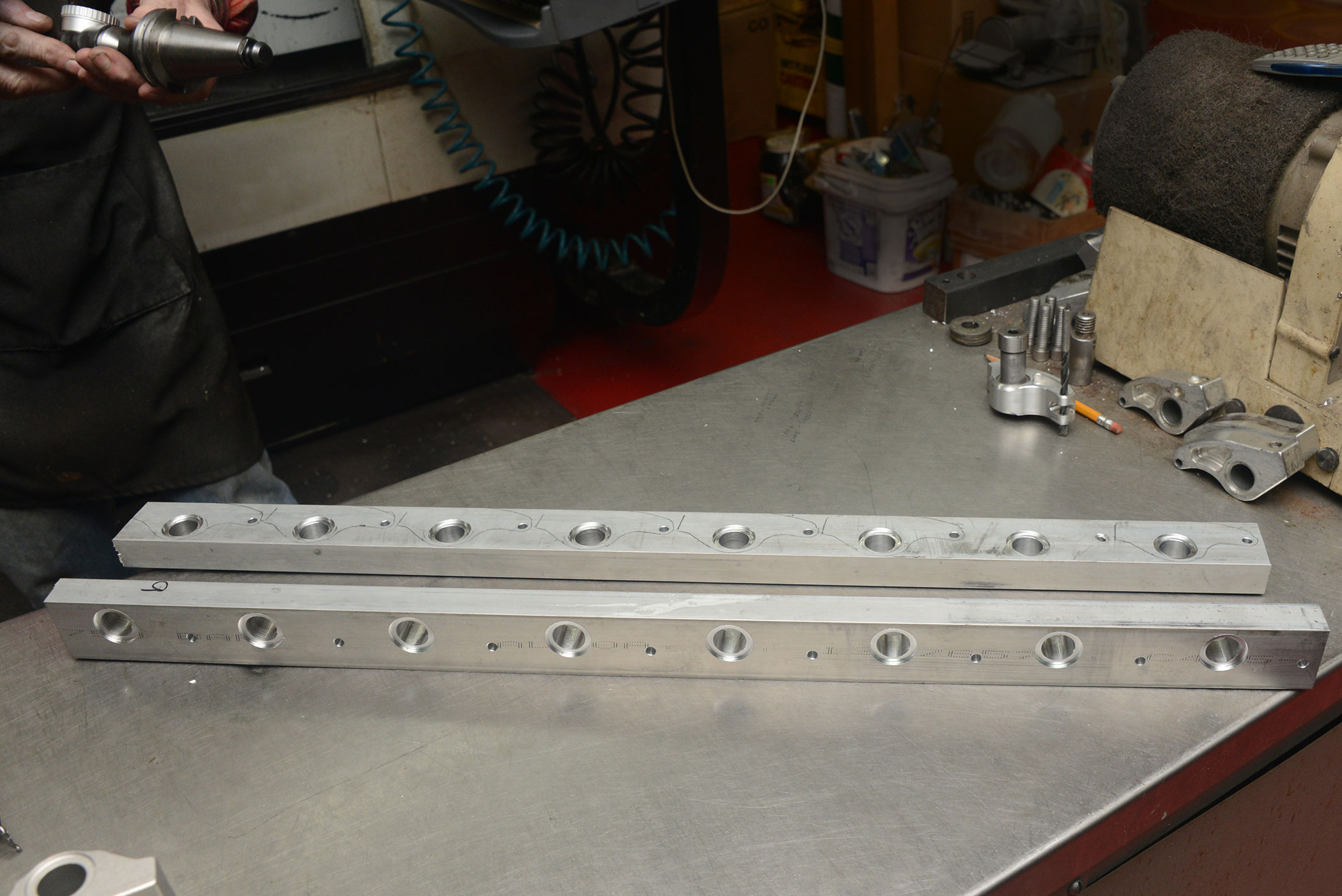

From these two bars of billet aluminum, 16 high-revving rocker arms will emerge. On the surface of each bar the profile of eight rockers are hand-scribed by pencil.

From these two bars of billet aluminum, 16 high-revving rocker arms will emerge. On the surface of each bar the profile of eight rockers are hand-scribed by pencil.

The trunnion holes (0.750in), their counter bores, and roller tip axle holes are already in place. For every $400,000 worth of rocker arms, Boutilier can count the failures on the fingers of one hand.

The trunnion holes (0.750in), their counter bores, and roller tip axle holes are already in place. For every $400,000 worth of rocker arms, Boutilier can count the failures on the fingers of one hand.

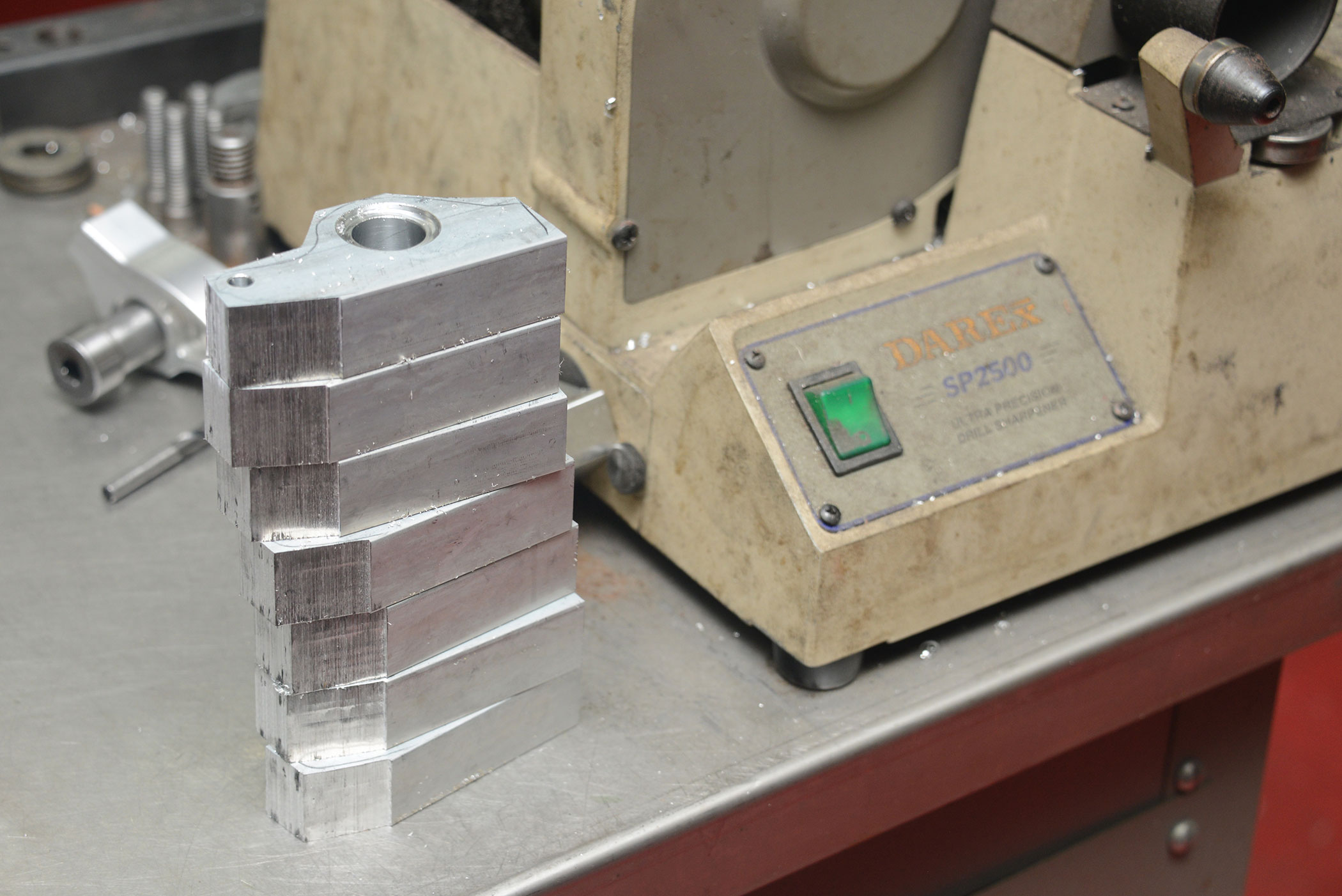

The pencil trace of each billet rocker arm is followed carefully by a band saw cut. The strength of the billet rocker is stated as 10 to 15 percent stronger than its extruded counterpart.

The pencil trace of each billet rocker arm is followed carefully by a band saw cut. The strength of the billet rocker is stated as 10 to 15 percent stronger than its extruded counterpart.

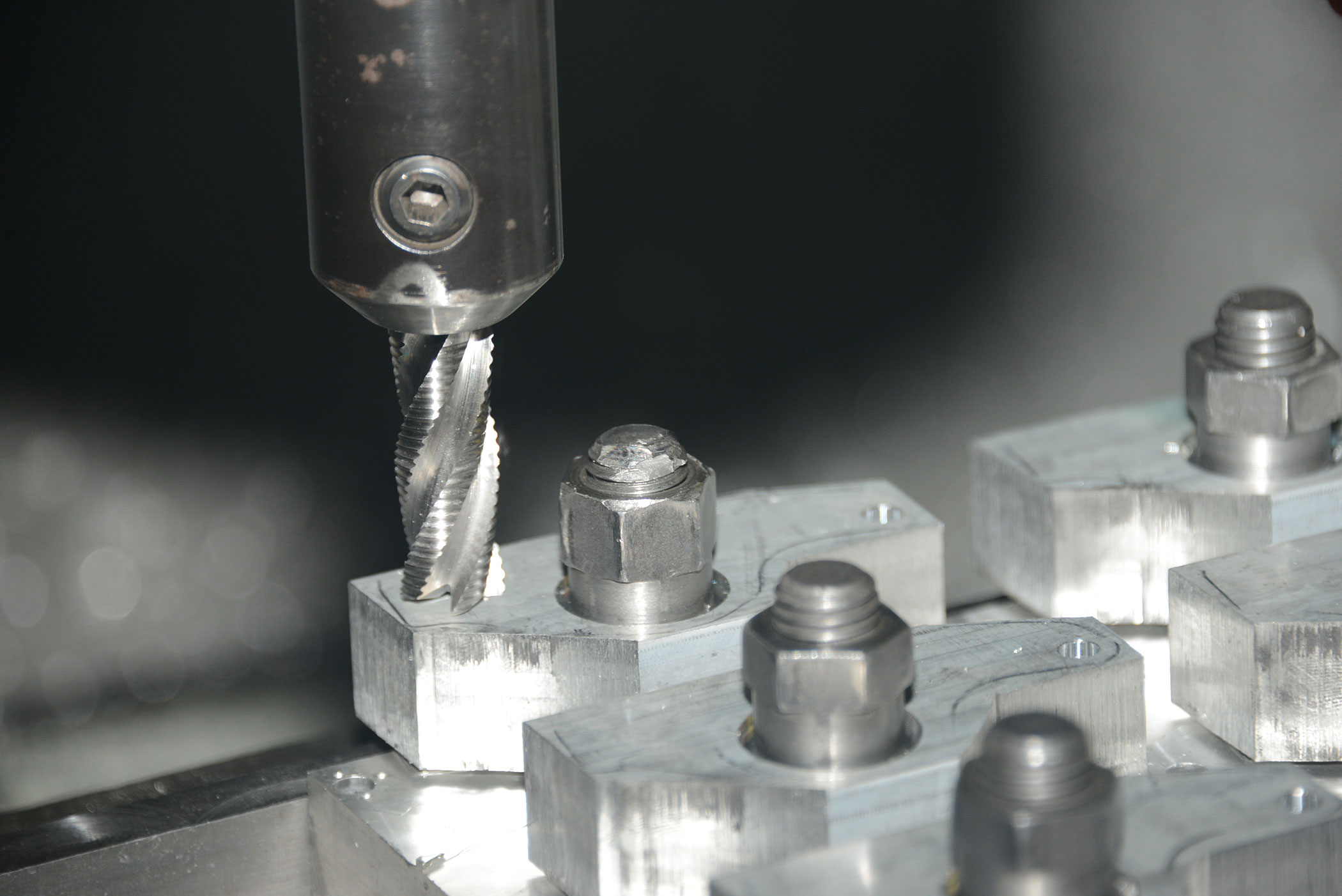

Following the band saw operation the rocker arm is ready for a machining process known as a roughing cut, which is followed by a smooth finishing cut.

Following the band saw operation the rocker arm is ready for a machining process known as a roughing cut, which is followed by a smooth finishing cut.

Unlike extruded rocker arms the grain structure of the billet runs down the bar longitudinally, as does the kinetic energy, and therein lays Boutilier’s advantage.

Unlike extruded rocker arms the grain structure of the billet runs down the bar longitudinally, as does the kinetic energy, and therein lays Boutilier’s advantage.

A wider radius is introduced to the area under the trunnion hole, thus the stand in which the rocker operates can benefit from a wider radius and thus greater strength.

A wider radius is introduced to the area under the trunnion hole, thus the stand in which the rocker operates can benefit from a wider radius and thus greater strength.

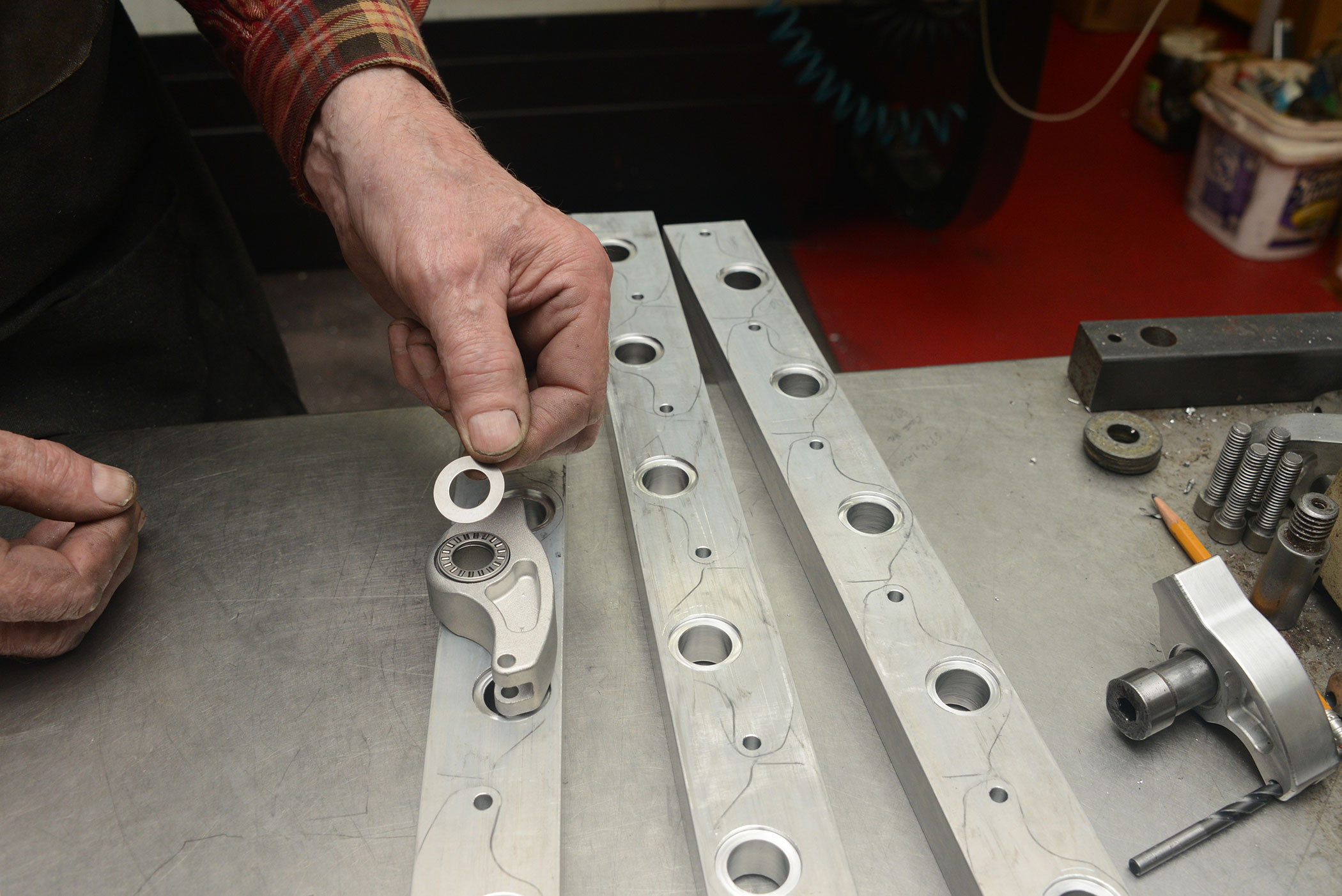

To reduce friction, two thrust shims, inner and outer, sandwich a thrust bearing in the counter bored hole in each side of these Pro Stock rockers. At the roller tip end a slot is machined and a hole drilled to accept an axle that is secured by a clip each end. The roller that rotates on the axle contains 22 tiny needle bearings. The clearance between the axle and the needle bearings is 0.0002in.

To reduce friction, two thrust shims, inner and outer, sandwich a thrust bearing in the counter bored hole in each side of these Pro Stock rockers. At the roller tip end a slot is machined and a hole drilled to accept an axle that is secured by a clip each end. The roller that rotates on the axle contains 22 tiny needle bearings. The clearance between the axle and the needle bearings is 0.0002in.

Once the rocker ratio is determined, any excess is trimmed off the adjuster end and its profile receives two 45-degree chamfers. Machined pockets are inserted for lightness. After the roller tip slot is executed the rockers are placed in a vibratory machine for de-burring, then shot peened. Finally a threaded hole for the rocker arm adjuster is introduced and the unit assembled.

Once the rocker ratio is determined, any excess is trimmed off the adjuster end and its profile receives two 45-degree chamfers. Machined pockets are inserted for lightness. After the roller tip slot is executed the rockers are placed in a vibratory machine for de-burring, then shot peened. Finally a threaded hole for the rocker arm adjuster is introduced and the unit assembled.