Before Pro Modified became an official drag racing class, there was Mike Thermos. His name has long been synonymous with nitrous oxide, and his innovations helped shape one of the most colorful categories in drag racing history.

Thermos is considered one of the godfathers of Pro Modified, not because he was the first to use nitrous, but because he made it accessible, reliable and widely accepted. From his early days in NHRA’s Funny Car ranks to the launch of Pro Mod through IHRA’s Top Sportsman and Quick Eight programs, his work influenced both the performance and the culture of the class.

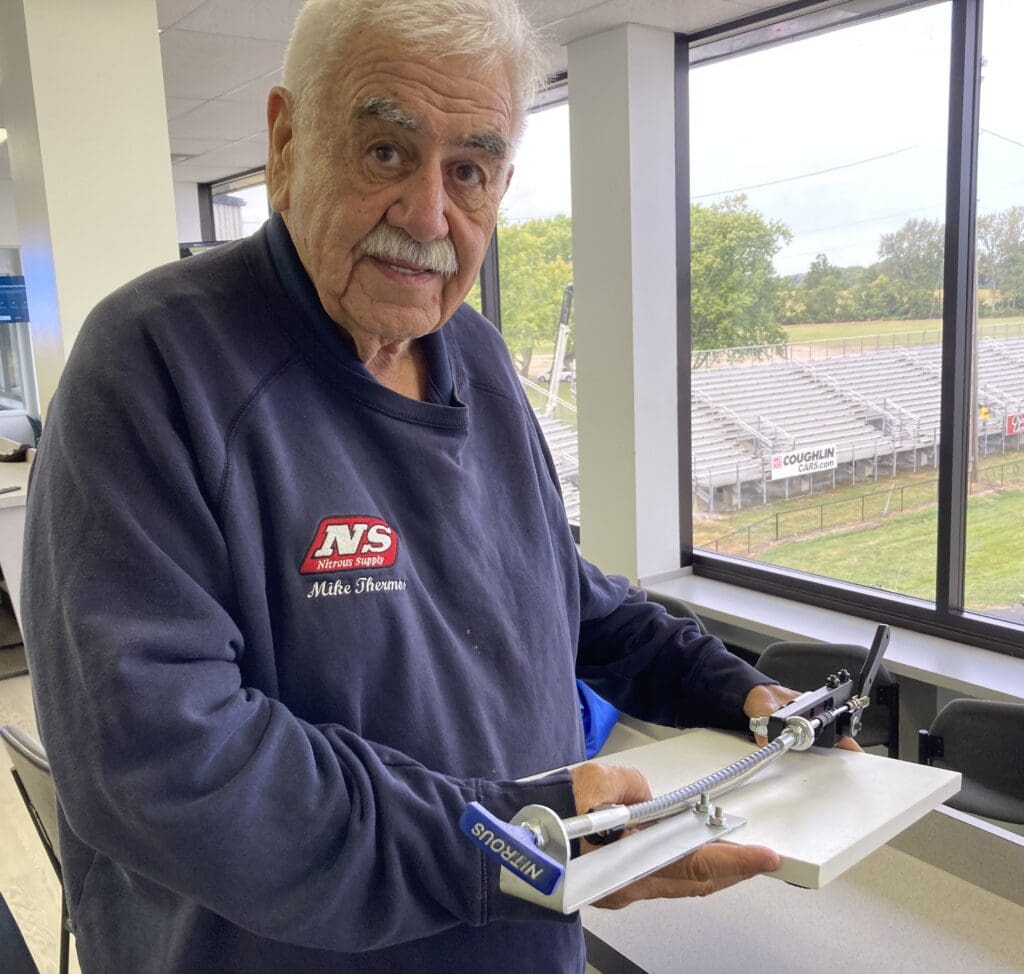

Now, after decades spent pushing performance boundaries, Thermos is focused on safety. His Huntington Beach, Calif.-based company, Nitrous Supply, has developed an inline safety valve aimed at addressing the hazards that come with high-pressure nitrous systems. The device adds an extra layer of protection for drivers and crews who face the risk of nitrous-fed fires.

“Well, the purpose is for safety,” Thermos said. “I mean, we’ve been seeing some things happen in nitrous and it doesn’t make sense because it’s so simple to cure it.”

The Inline Safety Valve is designed to shut down nitrous flow from two points. Drivers can use an in-car lever positioned near the thigh, while crew members or safety workers can access a pull handle mounted outside the car.

“It’s just a shut-off valve the driver could control from inside the car in a quick movement with his hand down by his thigh,” Thermos explained. “Or if he’s unconscious for some reason, there’s a pull that you just pull it on the back of the car coming out of the deck. And the starter can pull it or so anybody can pull it and shut off the nitrous.”

The design answers a long-standing problem in nitrous safety. Crashes or mechanical failures sometimes leave bottles flowing even after the ignition is cut, and traditional fire suppression can’t overcome the high-pressure stream.

“The problem comes from you can’t put the fire out with a fire extinguisher because the nitrous is coming out with 900 PSI and it blows all the fire extinguisher chemical away and the fire continues to burn,” Thermos said. “And nitrous is non-flammable, but it oxidizes what’s ever burning. So if your fuel pump’s on or there’s paint on the car and the car lights the paint, it’s going to burn and it’s going to burn very rapidly and very hostile.”

For Thermos, the dangers of nitrous are not abstract. He has spent more than five decades in the sport, from co-founding NOS to watching sanctioning bodies wrestle with how to regulate the power-adder.

“Yeah, we really started it with NOS and got here at IHRA and they allowed it to happen,” Thermos said. “Everywhere we went, we pretty much got banned because it was such an easy performance enhancement. And we were on fuel funny cars years ago and there was a lot of controversy and NHRA didn’t know how to control it so they banned it.”

While NHRA drew a hard line, IHRA embraced nitrous use in its Top Sportsman and Quick Eight programs. That decision gave rise to Pro Modified, a class built on accessibility and raw horsepower, where Thermos’ parts became commonplace.

But the performance edge came with risk. Thermos has always emphasized that nitrous is powerful, volatile, and demands the right equipment.

“Yeah, it’s an oxidizer and you got pressures to deal with in the approximately 1000 PSI,” he said. “So you can’t just use regular hose like you do for fuel and stuff. You have to have aircraft quality, I mean 3000 PSI hoses when you build a nitrous kit, otherwise you’re going to get in trouble. And the fact that it will enhance fires.”

Nitrous Supply also does nitrous refills, custom manifold plumbing and system analysis. Visit www.NitrousSupply.com or call 714-373-1986..

The chemical properties of nitrous make it unique. It does not burn by itself but can accelerate combustion and, under high heat, destabilize.

“There’s one thing that people don’t realize, that when nitrous reaches 570 degrees, it will actually create disassociation of the molecule. That’s where the oxygen comes from. And that has energy. And that can do all kinds, it can blow up a bottle,” Thermos said. “That’s why I see these guys with torches in the staging area with their bottle. That’s just insane. I mean, one of these days, if it reaches 570 degrees, it’s going to go into what they call abiotic, in chemist terminology. And the molecule splits.”

The new safety valve uses Nitrous Supply’s CNC-machined billet aluminum Outlaw Power Valve with a .500-inch orifice and internal porting for maximum flow. It is available in AN-6 or AN-8 line sizes and includes the external “T-handle” shutoff now required by some sanctioning groups. Associations have begun mandating external shutoffs after recent incidents underscored the need for safety personnel to have immediate control over nitrous systems.

Founded in 2004, Nitrous Supply continues to manufacture valves, nozzles, solenoids, and other components while also offering nitrous refills, manifold plumbing, and system analysis. For Thermos, the company is an extension of his lifetime of work in drag racing—balancing the relentless push for performance with an understanding of the dangers involved. He remains as committed today to safety as he was to innovation when Pro Modified first took shape.

“It doesn’t make sense to keep seeing the same problems when the fix is right there,” Thermos said. “If we can make it safer for racers, then that’s what we need to do.”