Geoff Turk is very goal-oriented, whether on the strip or off. Success is his primary goal, with failure not being an option.

Turk, using his Blackbird Performance brand, is determined to prove there’s a relatively low-cost engine platform, utilizing the Gen-3 Hemi platform, with parts readily available, that can be competitive in the high-demand arena of fast-bracket racing, primarily Top Dragster at this moment.

Understanding the category, which limits competitors to a 6.00 (3.60, eighth-mile) elapsed time, Turk understands the GM-dominated arena, with power adders, will be a formidable challenge.

“We want to show people there’s other options that are cost-effective and are very reliable, and have the performance capability to make a Top Dragster be a very solid, consistent winning race car,” Turk said. “We plan to prove there’s an option when it comes to utilizing a modern engine platform that the parts are really available and relatively inexpensive compared to other alternatives.”

Starting with Kevin Burnett, a Colorado-based Top Dragster racer, Turk said he would begin testing the new Blackbird Performance 1,675-horse engine combination soon.

“We came at it from two directions,” Turk explained. “Our Gen 3 Hemi knowledge began by trying to make a little bitty 345 cubic-inch, 5.7-liter engine run well in Super Stock. That was a 5.7 liter in a motor constrained by the rules of Super Stock. And then, obviously, in time, we migrated to supercharged engines that were smaller engines but supercharged in the NHRA’s Factory Stock Showdown.”

In racing those formats, Turk said he and his team learned how to make good horsepower with constraints and often wonders when freed, how well it could do.

“You start helping other people go fast, and there’s no rules,” Turk explained. “You can have more cubic inches. And all that stuff you’ve learned by having to squeeze everything out of a naturally-aspirated Gen 3 Hemi and then squeezing everything out of a highly rules-constrained, difficult 10,000 RPM, essentially race engine built on a Gen 3 platform, what you learn there when you get the opportunity to build something like a Top Dragster motor where you can put as many cubic inches as you want in and the freedom of choice for a supercharger, you really get to see the potential of what you can do.”

Turk’s development can be traced back to Super Stock racing in 2010.

“Turns out, it’s weirdly enough you find out as much working on the highly constrained, a little bit of cubic-inch versions of this motor as you do working with these big cubic-inch rules on limited motors,” Turk admitted.

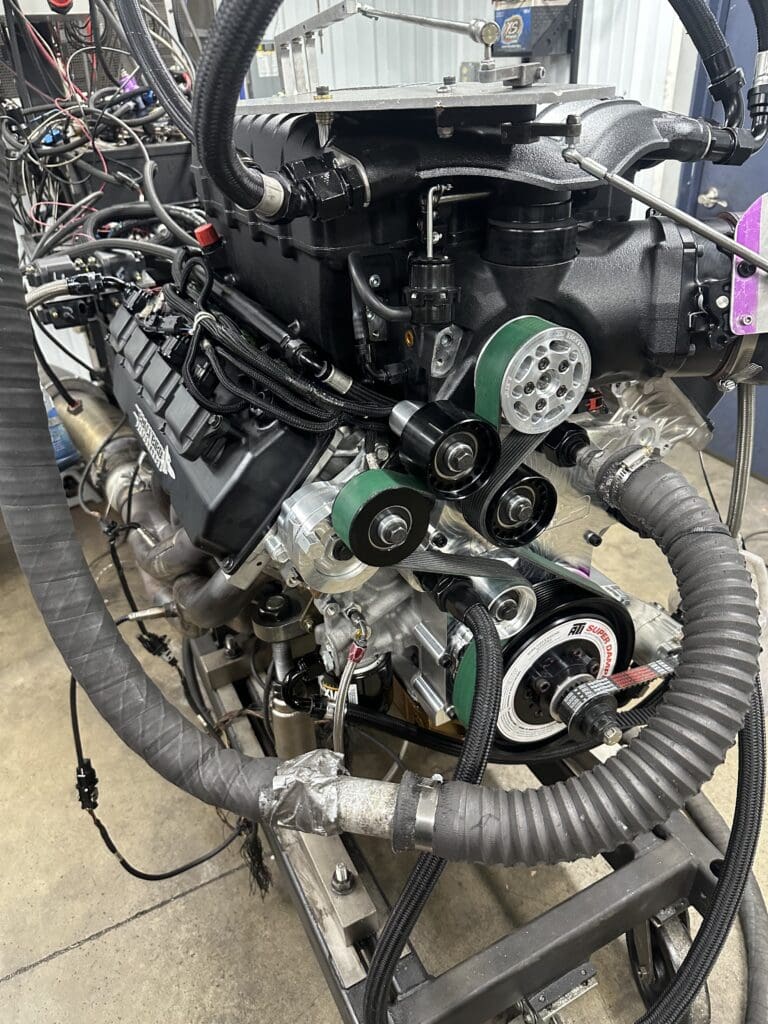

Turk’s 1,675-horse combination displaces 426 inches.

“It just simply has a small, essentially street-style Whipple supercharger, similar to what the Drag Paks run,” Turk said. “If you’re going to buy an aftermarket Whipple Supercharger to put on your street car and drive it 100,000 miles, it’s the about the same supercharger as that.”

Burnett is a Mopar racer, racing a 2019 M&M 247-inch four-link dragster. His previous combination was a Mopar crate motor which took a little while to dial-in when fighting tireshake issues. Those issues were solved with a torque converter switch at Turk’s suggestion.

“I consider Geoff probably the top tuner, builder of the Gen-3s anywhere, and when I met him up in Brainerd last year, and we just kind of got to talking, got to developing a relationship, and decided that this is a route we wanted to go this year to showcase his moto. I haven’t chased points for a long time, and I’m going to go ahead and do a NHRA points chase based out of Division 5.

“I’m very excited. With Turk in your corner and his support, I couldn’t pay for a college education that was better than having him back there helping me out.”

There will be key components from the Blackbird Performance manufacturing line in the 1675 engine, including the new Mach 4 camshaft, valve covers, timing chains, and gear set, as well as the supercharger tensioner and the tensioner bracket. Also in the mix is a new cylinder head configuration that is still in the development stage.

“This is a viable, cost-effective, reliable powerplant if you want something different than everybody else has,” Turk said. “Especially if you want a Mopar and you’re a Dodge guy, and even if you’re not a Mopar or a Dodge guy, the thing I’m trying to really get out there is, these engines can do everything an LS can, better and cheaper.

“As we keep working on these parts and coming out with very effective and cost-effective parts, the price to build one of these engines at this power level just keeps falling. Because we’re trying one by one to find the parts that are really the sticky point that you either can’t get, or it’s expensive, or it doesn’t work as well as you want and try to do those parts. That’s what we’re doing, and it, so far, seems like it’s working, so we’re going to keep at it.”

COMING NEXT – THE FIRST TEST AND WHAT IS LEARNED