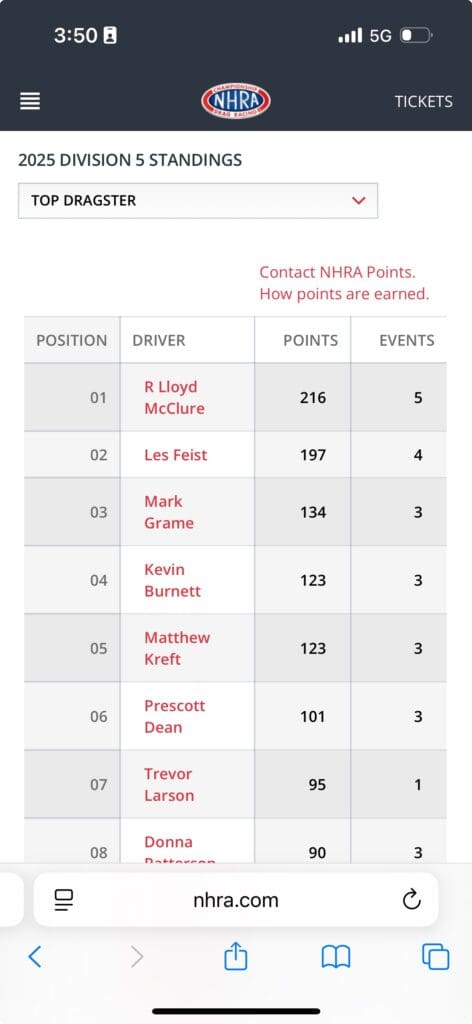

Project 1675, a collaborative effort between Blackbird Performance and Colorado racer Kevin Burnett, has completed three events with promising results as the team continues to test a crate-style Gen3 Hemi powerplant in a Top Dragster chassis.

Burnett and Project 1675 now have a national event round win and a semifinal finish — out of 24 cars — at the NHRA Division 5 event in Earlville, Iowa, to show for their efforts.

The program, designed to bring a more cost-effective and reliable option to fast bracket racing, is powered by a 1,675-horsepower Gen3 Hemi built by Blackbird Performance. It is the first car to utilize this package outside of Factory Stock and Factory X competition. In the team’s debut at the rain-plagued NHRA Division 5 double-divisional in St. Louis, they addressed torque converter and airflow issues that had limited early performance.

“St. Louis was a learning experience,” Blackbird’s Geoff Turk said. “We knew the torque converter was too tight, and we had to fix the air delivery to the blower — it just wasn’t efficient.”

The team installed a looser converter and a redesigned air scoop, based on a Factory X prototype, to solve airflow issues. The scoop was mounted behind the cockpit, an area previously prone to swirling air and heat coming off the radiator.

“We had a scoop design from another project that we’d helped with,” Turk said. “We adapted it and fabricated brackets to fit this dragster, and the improvement was clear right away.”

Those upgrades were in place when Burnett arrived at the national event in Joliet, where the car ran consistently in the mid-6.60s. An early belt-drive issue was resolved after the first qualifying attempt.

“He qualified mid-pack — I think 12th or 13th out of 27 — but we felt good about the car after fixing the belt,” Turk said. “He went rounds and drove well.”

Turk believes the project is now on the right path.

“It’s clear the car’s more competitive now,” he said. “The upgrades made a huge difference.”

The team also reviewed data from a previous double-breakout loss at St. Louis, where Burnett dialed a 6.47 and ran 6.457, while his opponent broke out by just .0012. Both drivers missed their dials by razor-thin margins.

“In that race, Burnett was going 212 and his opponent was going 222,” Turk said. “It showed we’re close — fast enough to be competitive but still efficient.”

That balance remains the project’s goal: to offer a durable and repeatable setup without relying on exotic or costly components to win in fast bracket racing.

“We’re running 6.30s to 6.50s efficiently,” Turk said. “That’s a sweet spot — fast enough to be competitive but more economical than chasing 6.10s.”

The dragster’s consistent performance against faster competitors suggests that outright speed isn’t always the deciding factor in bracket racing. Many winners in the class run mid-6-second passes, focusing on precision over power.

“Running mid-6s takes away a lot of the advantage from guys dialed in the 6.10 to 6.20 range,” Turk said. “And we’re doing it with repeatability and lower cost.”

Then came the breakthrough event in Earlville.

Burnett advanced to the semifinals, delivering a near-perfect reaction time of .0005 in the penultimate round. A malfunction in the intercooler pump caused a slight slowdown, contributing to a narrow loss.

“He still went 6.70 at 195, which is impressive given the water-flow issue,” Turk said. “The guy who beat him went on to win the event.”

Burnett said he’s encouraged by how quickly the program has come together — though there’s still work to be done getting the dragster and engine fully dialed in.

“It actually comes together pretty well,” Burnett said. “We’re still just kind of on the edge of what the chassis wants to take right now, so we’re still doing some chassis tuning and that kind of thing, just to get the car to be calm enough to leave the starting line.”

He noted that matching the engine to the chassis is often the biggest challenge.

“Getting the chassis and the engine on the same page almost always seems to be the biggest challenge,” he said. “The more power you put to them, the more finicky they get, as far as tire shake and that kind of thing.”

Burnett, typically guarded about his racing secrets, has grown more comfortable touting the combination’s strengths.

“It’s reasonably easy to operate,” he said of the 1,675-horsepower setup. “The engine produces great power. And reasonably low maintenance, as far as anything other than the normal oil change and checking the valves.”

He added: “I believe this is turning into a really good combination — and something that could be really good for someone in a Top Dragster, or even a Top Sportsman. I think we’re going to be competitive with pretty well most anybody at any given race.”

As the team wraps this phase of Project 1675, the plan is to finalize data analysis before potentially expanding the platform. Another version of the car could be in development soon.

“This might be the last outing for this edition of the project,” Turk said. “From here, we may move on to another build with similar goals.”

Project 1675 has already shown that pairing a crate-style Gen3 Hemi with a dragster platform can deliver bracket-competitive performance at a lower operating cost. As the NHRA season continues, its performance benchmark could shape how smaller teams approach Top Dragster racing in the future.

Looking ahead, Burnett plans to race at Brainerd, then Indianapolis, before returning to Earlville later this season.

“We’re just pushing forward and looking forward to much more racing,” he said.

.