Sometimes Patrick James wonders if he’s a little too innovative for his own good.

Quite often his innovative spirit yields a winner and for the owner and founder of Pro Systems, a high-performance carburetor manufacturer, his latest creation promises to be his best.

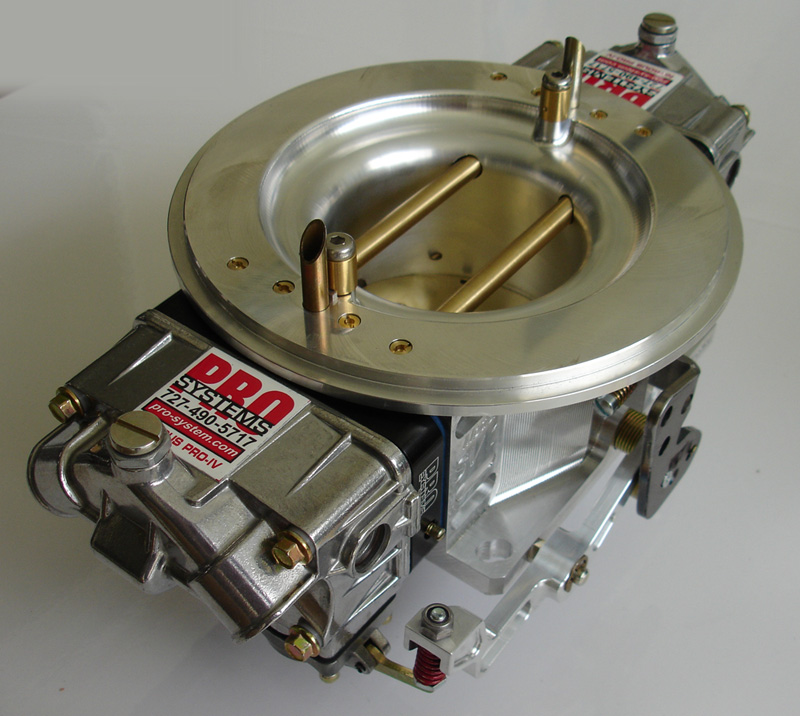

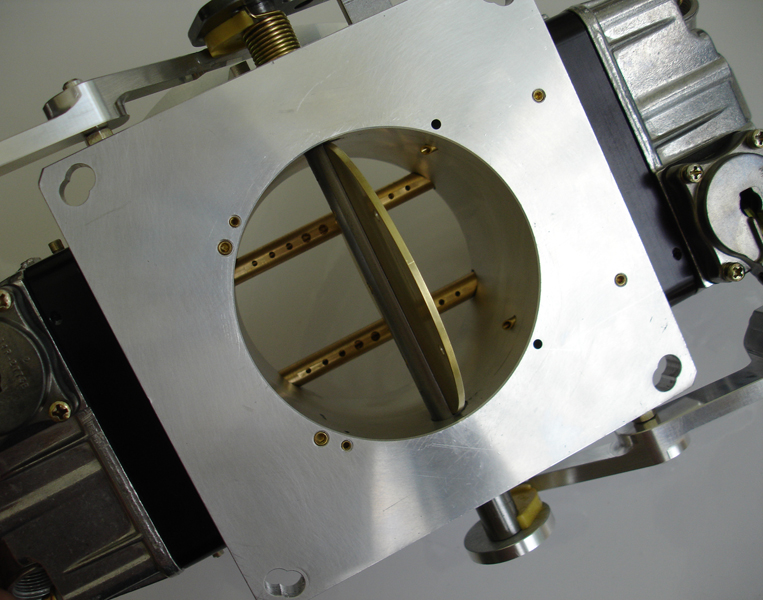

The Pro Systems SV1, according to James, is the first racing carburetor to incorporate a giant throttle blade into its design.

“The idea is to join all the engine pulses together, like a header collector,” said James, who has been in the carburetor business for 15 years.

Another characteristic of the Pro Systems SV1 is that it uses long boosters that are divided in half in the middle and with multiple holes along their length. They are then set low in the venturi. The objective of this configuration is to deliver better cylinder-to-cylinder distribution along with faster response to throttle movement and subsequent air speed changes, something James points out, the SV1 provides; 30 – 40 percent faster booster response time than the annular, dog leg and aerosol type boosters.

“In many of today’s currently marketed carburetors, the boosters lose much of their low speed and shift recovery signal as a result of the boosters signal generating center being placed directly over the center of the throttle shaft and blade,” said James. “This impedes the boosters low speed signal and shift recovery capability. But on the SV1, the whole booster length generates signal and distributes fuel. The shaft and blade placement is now no longer a factor due to this design feature.”

James contends that with the Pro Systems SV1, there’s more to the unit than just a single-venturi carburetor.

“It's shorter than both a 4150 carburetor and a Dominator carburetor so you have increased hood clearance and that’s a plus,” he continued. “However, one of the biggest pluses is the same carburetor bolts onto a 4150 or a Dominator intake manifold with no adapters required and it uses all standard Holley style jets, seals, metering, bowl and baseplate gaskets. So it's certainly versatile and it won't leave you stranded at the track needing custom tuning jets or gaskets.”

The SV1 is designed to be a monster of a carburetor. According to James, the smallest SV carburetor flows an actual 1100 real cfm but can be custom built to flow over 1250 and will still bolt onto a 4150 intake manifold with no adapters or modifications required. Pro Systems points out that this makes it the largest 4150 bolt pattern carburetor on the market

“With its high signal generation you can run a larger carburetor than normally allowed as compared to conventional carburetor designs,” James added.

Pro Systems also states that the SV1 can be bored out to exceed 2600 cfm but in doing so, the engine builder must move it over onto a Dominator intake manifold.

So what was the primary goal of the SV1?

“It’s a culmination of ideas that should have been done years ago,” James said. “But lately the nitrous racers with their super tight converters have forced its existence.” He further explains, “We feed a very large contingent of nitrous racers that struggle to get their programs to stage against their tight nitrous converters. This carburetor gathers so much signal that it will jump up on anything. So nitrous racers can run even tighter nitrous converters and gain more mph when using the SV1.

“From off idle, the first change to air velocity is at the venturi edge. So the booster needs to be there to sense that change to improve throttle response to get the metering system primed and get your engine up on the converter. This booster layout does just that. The second change in air velocity is during the shift and the engagement of nitrous, so you need the fuel passage to be as straight a shot as you can make it and have the air velocity pulse unobstructed by the throttle shaft and blades. Changing directions and confusing passages, like circular fed annular boosters, angled fuel port dog leg booster passages and imposing throttle blades, block the initial pulse and slow the response time. Also with the long and low booster design, you expose the booster to as many areas of the venturi as possible to improve communication. The SV1 can sense those changes in velocity (from center to edge) and has made it the fastest responding layout we've ever tested.”

James confirmed the first area to be tested on the SV1 was the throttle response.

“The moment we got the prototype fired up, we installed the 1100 cfm version on a 400 horsepower street engine with a 3000 stall converter and it jumped right up against the converter instantly and sat there … dead stable at 13:1 air to fuel ratio … so we knew we were onto something.”

Quicker response time is most vital with the introduction of each nitrous stage or gear shift. This is aimed to improve the stabilization of the engines tune-up with lesser likelihood of leaning out the engine during these transitions.

For the non-nitrous racers, primarily those who bracket race and employ throttle stops, an instant response time eliminates those lean spikes and beefs up consistency.

“Idle quality is always a big concern with racers as well, especially in a nitrous engine,” Patrick explained. “Nitrous engines operate with very cold spark plugs, so plug fouling is a common occurrence. The SV1 has a very unique idle circuit configuration designed to really atomize the idle fuel and give it an improved idle quality.

“We initially tested the idle quality on one of our shop test cars. This car is equipped with a 540 cubic inch engine that previously preferred to idle at 1300 rpm … anything lower and the engine was unhappy and temperamental. The SV1 allowed the engine to easily idle at 900 rpm all day long and fire back up at the tap of the starter button.”

Time will tell if the SV1, as James claims, is possibly the last great innovative carburetor design.

But as James says the CNC machine work does look like a "work of art" and James states that all of the SV1's exclusive components are designed and manufactured here in the United States. So thats good for us.

“It’s not a new twist on an old idea,” James also contends. “This is some very out of the box thinking with no apparent limitations ... unless you call a 2600 cfm carburetor a limitation.”

Pro Systems would like to express thanks to the companies that assisted them in the development of this product’s design: B.E.S., Glidden Racing, Midwest Engine Tech, SMRE and Induction Solutions.

For more information on the Pro Systems SV1, visit their website at www.prosystemsracing.com.