PROJECT WHITE WAGON – HEAD GAMES

The cylinder head to a Competition Eliminator-style Super Stocker is the equivalent of a foundation for a home. You begin with the cylinder head and build your engine around it.

The leader in Super Stock cylinder head technology is Carl Foltz’s CFE Racing Products, Inc.

“The cylinder head is a key ingredient in a powerful racing engine,” confirmed Scott Kieffer, a sales and technical support agent for CFE. “The other elements of the engine will be determined by the direction of the cylinder head.”

Kieffer’s boss has been around cylinder heads for many years.

Every good engine starts with the cylinder heads The cylinder head to a Competition Eliminator-style Super Stocker is the equivalent of a foundation for a home. You begin with the cylinder head and build your engine around it.

The cylinder head to a Competition Eliminator-style Super Stocker is the equivalent of a foundation for a home. You begin with the cylinder head and build your engine around it.

The leader in Super Stock cylinder head technology is Carl Foltz’s CFE Racing Products, Inc.

“The cylinder head is a key ingredient in a powerful racing engine,” confirmed Scott Kieffer, a sales and technical support agent for CFE. “The other elements of the engine will be determined by the direction of the cylinder head.”

Kieffer’s boss has been around cylinder heads for many years.

Foltz’s career in cylinder head technology began over a quarter-century ago when someone brought in an engine built by Pro Stock legend Bill “Grumpy” Jenkins. Foltz worked countless hours crafting a custom sheet-metal intake manifold and devoted just as much time testing and retesting his unique cylinder head design on a flow bench. The end result was 60 more horses and a new business.

“Making more power has been my passion forever, since I was a kid,” said Foltz, 48. “You have dreams of accomplishing something like that, but we didn't win those championships, our customers won them. I could give a set of heads to other people, and they wouldn't win a thing.”

Foltz leads a dedicated staff in a state-of-the-art facility using five-axis machining centers. In the beginning, it was just him.

“I've been porting heads since I was 15 years old, in the late '70s, which was a great time to start,” Foltz said. “That's when flow benches were just coming out.”

Running the CFE Cylinder Heads and intake, our Project White Wagon will be running with fast company. Currently as many as 30 different Comp and Super Stock drivers running CFE components hold national records.

Grant Lewis holds the Super Stock/E Modified class record with a 9.01 elapsed time at 147.33 miles per hour. He runs the CFE wedge cylinder heads.

a d v e r t i s e m e n t

Click to visit our sponsor's website

The original White Wagon was a very flexible car, running the gamut of the second-half Modified Production classes – D through H (once upon a time before it was a six-cylinder division). Original car owner Gene Fulton ran various engine displacements ranging from 262 cubic inches to 350.

We have selected the classification SS/E Modified, an 11.5 to 12.49 pounds per cubic inch class. Obviously this will require a special style of engine different from your average Super Stocker.

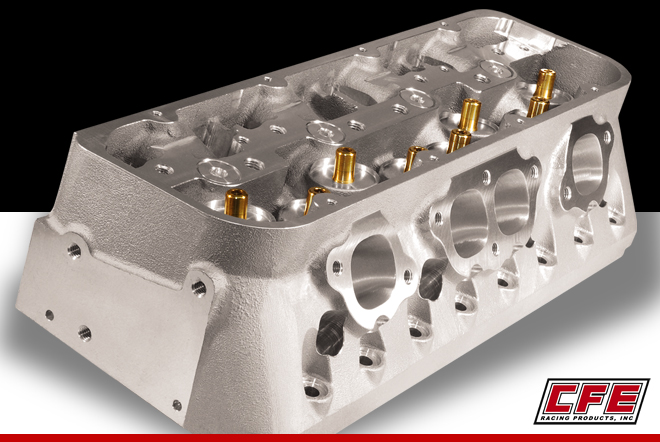

Upon the advice of CFE, our White Wagon will begin with a set of SB2.2 cylinder heads.

To begin charting the pathway, we had to determine our objectives. This wagon will use a 292 cubic inch Chevrolet aimed at producing 800 horses and gunning for the high eight-second range.

Determining your objectives for the future will go far towards creating fewer headaches in the present.

“Obviously, if the goal is to produce 1000 horsepower from a 400 cubic inch small block, let’s say a B/Altered or an Australian Pro Stock, anyone with any knowledge wouldn’t attempt such a project with a standard 23-degree head,” explained Kieffer. “It won’t support the objective. The head selected to do the job then determined the other items below the cylinder heads such as bore size, head bolt pattern, valve train, piston design and manifold selection.

And for our SS/E Modified car, the equivalent of the old E/Modified Production class, CFE’s SB2.2 fit the bill.

“We evaluated what was permissible through the NHRA rulebook and is generally available with the limitation of two valves per cylinder with an OEM part number cast onto the head,” said Kieffer. “The rules for E/Modified state that we are allowed the option of a canted or inline valve head. There are no weight penalties for either cylinder head. Taking these parameters into account, the SB2.2, because of its canted valve arrangement, would offer some advantages over a true wedge head.”

The SB2.2 isn’t your typical assembly line to the box cylinder head.

The SB2.2 comes from GM with much of its exterior machine work already done. This means the bolt pattern for the head stud columns, intake manifold bolt holes, exhaust header flanges and the rocker stand holes are already established. The castings are made with fairly small port cores (or openings) so there is plenty of material to allow for manipulation of the port shapes and sizes for various applications and different size engines. This provides the head porter with a little more latitude in what he can do with the head and get adequate clean up to be able to move the ports around to achieve certain objectives.

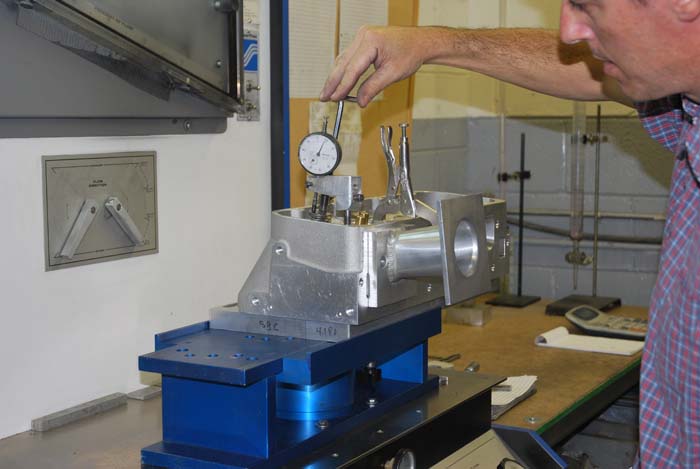

“Our role with the preparation begins with the installation of special alloy valve guides and seats,” explained Kieffer. “We CNC port the intake, exhaust and combustion chambers and the heads are ready for guide honing and a valve job.”

Once the seats are cut, according to Kieffer, the final detailing is performed by hand and the heads are decked (or resurfaced) to a predetermined volume discussed with the customer to achieve the desired compression ratio. The finished heads are then pressure checked, final inspected and are ready for assembly of the valves and springs.

When we originally set our game plan for the engine, we had mapped out everything from the horsepower to the components to the bore and stroke.

We had planned to use a 3.935 bore and a 3-inch stroke. This initial plan was scrapped because the initial bore size would have been too small because of a lack of radial clearance of the cylinder wall.

“In other words the valves would be too close to the bore with the previous diameter,” Kieffer explained. “Opening up the bore to 4.125” or bigger will allow the valves to be un-shrouded. This will make the engine much more efficient for its intended application.”

As a footnote, there’s an additional advantage, less stroke will reduce friction which in turn will increase the efficiency of the engine for its intended 10,000-plus rpm range.

a d v e r t i s e m e n t

Click to visit our sponsor's website

Kieffer confirmed the cylinder heads will dictate the way we prepare the block, BME rods and pistons as well as the Winberg crankshaft.

“The heads will have a direct impact on the rest of the engine parts but in the case of the block, to gain maximum efficiency, we will have the tappet bores relocated from the OEM position in an effort to straighten the pushrod angles. The block’s height will be partially influenced by manifold design.

“If the deck height is too tall, the plenum design will be compromised,” Kieffer warned. “The piston design parameters that are influenced by the cylinder head are the dome shape, dome volume, valve reliefs and ring placement. Rod length and crankshaft stroke are also indirectly influenced by the cylinder heads largely because of those factors above them.

“The bottom line is to design an engine, you begin from the cylinder head and work down, not from the crankshaft and up.”

According to Kieffer, with the combination of the CFE SB2.2 heads along with the CFE sheet metal intake manifold [which we will discuss in a later installment], 800 horsepower with quality supporting parts, is very much attainable.

“This should be achievable based on current power levels for similar engines in the field that we have done head and manifold work on.”

SOURCE

CFE

Scott Kieffer

16834 Chesterfield

Eastpointe, MI 48021

586.773.6310

www.cferacing.com

COMING UP NEXT: PART 5, PREPARING THE BODY WITH AN EMOTIONAL TWIST

PAST INSTALLMENTS

* Part 1, Outlining The Project

* Part 2, Getting The Car on The Jig

* Part 3, Preparing for the 4-Link

PROJECT WHITE WAGON SUPPORTERS

TL Race Cars (864) 427-5269

Fluid Power Specialties (864) 599-1118

Minton's Wrecker Service (864) 474-2581

Fulton Competition

PART SUPPLIERS

A.E.D. Motorsports Products (tubing)

Applied Racing Technologies (A.R.T)

Aeromotive Inc. (fuel system)

Autometer Guages (tech, engine gauges)

Bill Miller Engineering (rods, pistons)

Browell Bellhousings (bellhousing)

CFE Heads (cylinder heads, intake)

CFM Composites (seats)

Carson's Nut-Bolt and Tool

Comp Cams (camshaft)

Dart Engineering (Engine Block)

Flatout Gaskets (engine gaskets)

Hedman Headers (headers)

I.R.C. (wheelie bar wheels, bracketry)

Jegs Mail Order (misc.)

J&W Nova Parts (body panels and body sheetmetal)

Liberty's Transmissions (Transmission, Gears)

Matco Tools - (tools, tool box)

Mickey Thompson Tires & Wheels (front tires, slicks)

Moroso Performance (valve covers)

QA-1 (Rod Ends)

Quartermax Racing & Chassis Components (suspension, chassis components, axles)

Ram Clutches

Santhuff Shocks (front, rear shocks)

Simpson Safety - (Helmet, Firesuit)

Strange Engineering (Axles, Rearend companents)

Weld Racing (front, rear wheels)

Winberg Crankshafts (crankshaft)