PROJECT WHITE WAGON: NOW THAT’S A REAREND!

Now we’re getting ready to install the RJ Race Cars 9-inch Ford housing into the Project White Wagon. At this point, the unit is sitting on the TL Race Cars work bench, with chassis builder Tom Lukans carefully measuring and configuring the driveline placement.

Now we’re getting ready to install the RJ Race Cars 9-inch Ford housing into the Project White Wagon. At this point, the unit is sitting on the TL Race Cars work bench, with chassis builder Tom Lukans carefully measuring and configuring the driveline placement.

“We know that the centerline on the car is off-set by half-inch,” Lukans explained. “The plate we have designates the centerline. From here we know where the center line is on the pinion. If we want the pinion offset to the passenger side, we off-set by a half-inch using the plate to measure. We incorporate the Quarter-Max four-link brackets and we are working on the back brace right now. Once we get this assembled we can work on the rearend.”

The unit isn’t race ready for our application, and does require a little work. But, for Lukans, the RJ Race Cars unit is one of the finest he’s ever worked with.

“It requires a lot of time and welds and these welds are intricate,” Lukans said. “You’re looking at something which will need a lot of strength. This RJ Race Cars Quarter-Max Rearend is a high-quality piece. When I’ve welded on it, there is no weak link. It’s high quality metal. You don’t get that from every manufacturer.”

Now we’re getting ready to install the RJ Race Cars [Quartermax] 9-inch Ford housing into the Project White Wagon. At this point, the unit is sitting on the TL

Race Cars work bench, with chassis builder Tom Lukans carefully measuring and configuring the driveline placement.

“We know that the centerline on the car is off-set by half-inch,” Lukans explained. “The plate we have designates the centerline. From here we know where the center line is on the pinion. If we want the pinion offset to the passenger side, we off-set by a half-inch using the plate to measure. We incorporate the Quarter-Max four-link brackets and we are working on the back brace right now. Once we get this assembled we can work on the rearend.”

The unit isn’t race ready for our application, and does require a little work. But, for Lukans, the RJ Race Cars housing is one of the finest he’s ever worked with.

“It requires a lot of time and welds and these welds are intricate,” Lukans said. “You’re looking at something which will need a lot of strength. This Quarter-Max Rearend is a high-quality piece. When I’ve welded on it, there is no weak link. It’s high quality metal. You don’t get that from every manufacturer.”

You’ve heard the old Secret deodorant commercial, a product made specifically for female consumers, and to us, this unit fits the same ideal. Strong enough for a Pro Stocker, but made for a Super Stocker.

“When you drop the hammer on this thing, at 10,000 rpm, you’re going to take a serious shot in the hip. A 3,300 pound car with 420 foot pounds [torque=(5,252X HP (divided by RPM of torque). People don’t realize the torque these cars put out. That’s why we have heavy duty parts.”

Being overqualified with our Super Stocker isn’t something out of the ordinary lately.

“This is quickly becoming the norm, Super Stock cars with the same rear-ends as Top Sportsman and Pro Stocks,” said Lukans. “With today’s tires and tracks is why this has become the norm. This housing wasn’t even considered back when the original wagon ran. The stock unit has become so much work just to get up to today’s standards. I don’t even fool with the stock units today.”

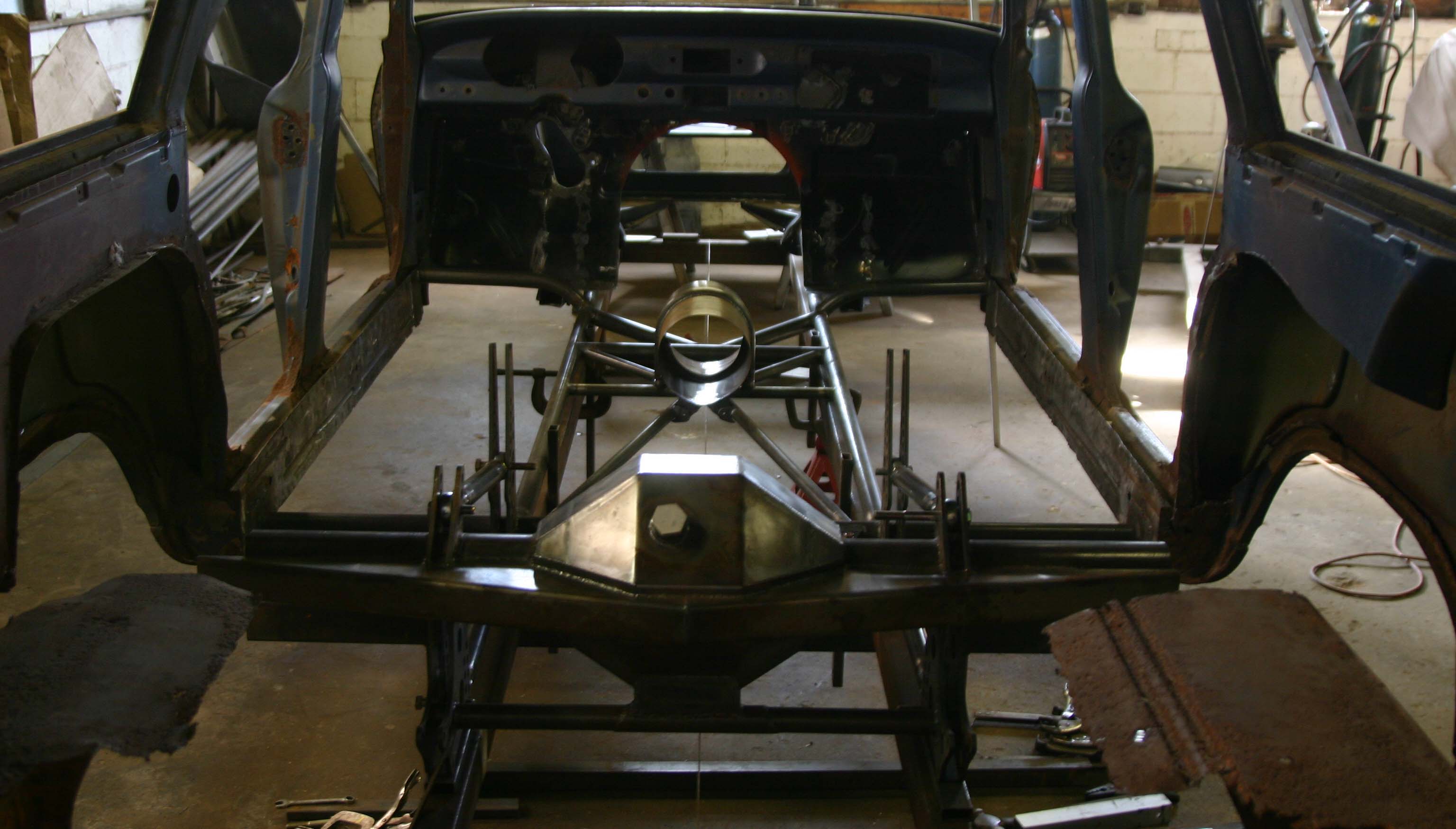

LAYING PIPE …

We’ve started installing tubing now that we have a lot of the preparation work completed and the two frame rails will serve as a starting spot. These rails, as specified by SFI specifications, are 1.5-inch, .065 thickness tubing.

This has been followed by the X-bar along with the removable driveshaft safety tunnel. At this point, the floor pan will still move in and out of the car but will soon become permanently attached.

The driveshaft tunnel is offset a half-inch to the passenger side.

“What we have to do at this point is make sure the rear end, where the pinion is, the back of the transmission is, front center of the motor everything lines up on that centerline of the car,” said Lukans. “This will be the rule for what we build and measure on from now on.

“You want that driveshaft to be straight onto that transmission. For it to be off of line, will scrub off ET and mile per hour. This is exactly like line honing an engine. This time it’s a full car.”

In filling the RJ Race Cars housing, there was only one logical choice for Lukans and that was with Strange Engineering components. Lukans, who bought his first Strange products in 1978 from the legendary Herb McAndless, has used their products exclusively for many years.

The center section from Strange Engineering is a major step up from the unit used in the original White Wagon in the 1970s.

“The engineers at Strange have used a solid works design program to come up with what was needed to reinforce these 9-inch housings,” Lukans said. “The new case we are using is a little lighter than their original lightweight nine-inch case. It’s essentially a cross between the Ultra Center Section and the lightweight aluminum case.”

This unit, labeled as the 9-inch Heavy-Duty Pro Aluminum case [Part No. 2303], is likely the same kind you will see on a Pro Modified, Pro Stock or Comp style car.

“With the engines, clutches, converters, tires and tracks getting better, you need something that’s going to go to the next level of stability,” said Lukans. “The center section with the billet main caps on the back, stabilizing the rearend housing through bolt studs, provides better ring life and puts less stress and deflection on the ring and pinion gear.”

On a nitrous Pro Modified car, the ring and pinion gear can usually live through 60 – 80 passes. Project White Wagon should get about 400 runs before we need to start switching parts out.

“This center section has better oiling for the front bearing where you put the bigger taper roller bearing in there,” Lukans said. “This ensures the bearing runs cooler and you’re less likely to have a bearing problem. This also works to extend the life of the ring and pinion.”

For the ring gear, we have chosen to go with the 6.20 ratio [RPM at finish line X Tire Diameter divided by mile per hour X 336] because experience tells us that with the 5-speed and engine combination, this will be an optimum starting position just by factoring the numbers.

The ring gear has been lightened by removing the reciprocating weight before it even reached our shop thanks to an option from Strange. This does not hinder the strength of the ring and pinion whatsoever.

Our choice of axle is the 40-spline, gun-drilled lightweight package [P1015] for a combination of lesser weight and dependability.

We also added the bigger symmetrical housing ends which in turn enabled us to use Strange’s A-1024 axle bearing assembly for added stability.

A testament to the quality and detail of the RJ Race Cars rearend, is that the unit mated perfectly with the Strange components.

“That certainly makes life a lot easier for someone assembling these things,” Lukans added.

In the last few weeks, Lukans has spent an inordinate amount of time at the shop as the Project White Wagon comes together with an expected debut at the 2012 NHRA Thunder Valley Nationals in Bristol, Tenn.

“I’ve gotten to where I don’t even want to leave the shop at night,” said Lukans.

PAST INSTALLMENTS

* Part 1, Outlining The Project

* Part 2, Getting The Car on The Jig

* Part 3, Preparing for the Four-Link

* Part 4, Preparing the Cylinder Heads

* Part 5, Project Gains A Purpose

* Part 6, Shocking the Wagon

* Part 7, A Real Clutch Player

* Part 8, Nova Body Parts Done Right

* Part 9, Space Age Intake Meets The Basket Case

* Part 10, Dart Aftermarket Blocks Poised to Fly in Stk/SS

* Part 11, We Are Rolling Again

PROJECT WHITE WAGON SUPPORTERS

PROJECT WHITE WAGON SUPPORTERS

TL Race Cars (864) 427-5269

Fluid Power Specialties (864) 599-1118

Minton's Wrecker Service (864) 474-2581

Fulton Competition

PART SUPPLIERS

A.E.D. Motorsports Products (tubing)

Applied Racing Technologies (A.R.T)

Aeromotive Inc. (fuel system)

Autometer Guages (tech, engine gauges)

Bill Miller Engineering (rods, pistons)

Browell Bellhousings (bellhousing)

CFE Heads (cylinder heads, intake)

CFM Composites (seats)

Carson's Nut-Bolt and Tool

Comp Cams (camshaft)

Dart Engineering (Engine Block)

Flatout Gaskets (engine gaskets)

Hedman Headers (headers)

I.R.C. (wheelie bar wheels, bracketry)

Jegs Mail Order (misc.)

J&W Nova Parts (body panels and body sheetmetal)

Liberty's Transmissions (Transmission, Gears)

Matco Tools - (tools, tool box)

Mickey Thompson Tires & Wheels (front tires, slicks)

Moroso Performance (valve covers)

QA-1 (Rod Ends)

Quartermax Racing & Chassis Components (suspension, chassis components, axles)

Ram Clutches

Santhuff Shocks (front, rear shocks)

Simpson Safety - (Helmet, Firesuit)

Strange Engineering (Axles, Rearend companents)

Weld Racing (front, rear wheels)

Winberg Crankshafts (crankshaft)