A PERFECT MARRIAGE: RACING’S BUSINESS SIDE BUILT OFF OF REAL-WORLD EXPERIENCE

Mixing business with pleasure, it is an exercise that is so often cast in a negative light.

Mixing business with pleasure, it is an exercise that is so often cast in a negative light.

How often are we told not to let work interfere with our hobbies and the things we are passionate about away from the hustle-and-bustle of daily office life.

But what if your business is your pleasure?

Welcome to the world of drag racing’s unique entrepreneurs.

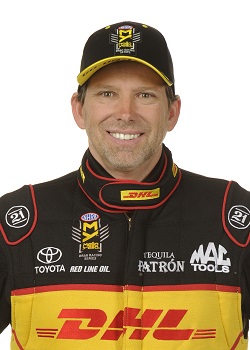

For someone like two-time NHRA world champion Del Worsham and his crew chief Nicky Boninfante, there is no separating the two. Their passion for racing goes hand-in-hand with their endeavors away from the racetrack. It is a marriage born out of necessity and one that has led to some big breakthroughs, along with more than a few learn-from-your-mistakes moments.

“The business side of what I do goes hand-in-hand with my involvement with this race team,” said Boninfante, co-owner of Boninfante Friction and crew chief for Worsham’s DHL Toyota Camry Funny Car. “I used to spend a lot of time in the shop and I learned a lot about clutch parts and what works well, not just for our car, but what works well for other teams as far as clutch torque differences, the way we build our floater plates. What I have been able to do is pass the on-track knowledge on to the business side of things and help, not just our own team, but build good, quality parts that are reliable for the teams and what they need.

“Between me and my brother’s knowledge, we have been able to take our whole on-track experience and develop parts that are built around what the racer or the tuner really wants. Instead of saying, ‘here is a part, this is what we have, you figure out how to make it work,’ we can take real-world experience and apply it to the business side.”

For Boninfante, who is the posterchild for mixing work with his passions, the things he sees on weekends at the racetrack directly impact the business side of his life. From new part development, to massive gains in the improvement of current products, his experiences living and breathing racing have led to some cutting-edge breakthroughs at Boninfante Friction, one of the world leaders in friction clutch manufacturing in motorsports.

“Several years ago we had a very good relationship with Austin Coil. Austin ran John Force’s car forever and they won a ton of championships together. One day, Austin came to us and wanted to get a clutch disc that, in his mind, had ‘more authority’ and worked really well under all conditions,” Boninfante said. “Austin spent a good two years and a fair amount of John’s money working with us to develop a clutch disc that, at the time, we could only sell to John Force Racing.

“What we learned along the way developing the clutch disc, my brother and I were able to put that input into those discs. When we came up with the special batch for Austin, they ran them for a year and did pretty well with it. They were obviously already ahead of everybody at the time and they stayed ahead. As the years went on, we tweaked that mix and other mixes and came up with some improvements and were able to tailor it to what certain teams wanted.”

Other times, Boninfante says that shifts in the industry itself have opened up new avenues for the company.

“Well, when Connie Kalitta asks you for something, you are not going to tell him no. My brother and I went back, learned everything we could about copper, we hired all the right people and we came up with a process to build a head gasket that was better than everybody out there.

“About six months and a ton of money later, we took Connie a gasket and he liked it, so we moved on to building gaskets for Kalitta Motorsports. Once word got out, guys starting calling us, asking what it is going to take to buy them. Finally, enough teams called and Connie said we could sell them to everybody.

“We were in the clutch business and had no interest in the gasket business, but we built it. Today, a lot of fuel teams run our gaskets. It is how we live, if you can’t get something you need, you build it. That is how we built this company.”

Of course, Boninfante is not the only man in the pits living the double-life as racer and savvy businessman. Defending Funny Car world champion Worsham also dabbles in a few side ventures that are made possible through his on-track experiences.

From licensing and upgrading up-and-coming drivers in Top Fuel and Funny Car through cars that he and his father own, to helping racers out with their fuel systems, Worsham uses his own personal racing knowledge and applies it to projects that, in-turn, vastly help others.

All while trying to manage a full-time operation for Kalitta Motorsports as a championship-level NHRA Funny Car team.

“I spend a lot of time working on fuel systems and I really like to dial them in and do something a little different sometimes,” Worsham said. “I am pretty lucky; the work I do. My actual job racing for Kalitta and driving this Funny Car allows me to keep my skills honed and I am around the cars and I keep updated information, so when I go to help out with fuel systems, I am already a part of a team where we work on it. I can save you a run or two and get your system close to how it is going to run on the car.

"And when we go to license people, I am a licensed driver, still out here racing, and I can offer knowledge and help people who are up-and-comers and want to be professional racers.”

And, like Boninfante, it is the expertise that comes with years of experience that make all the difference.

“Growing up around Top Fuel and Funny Cars, I have watched the progression of where we started back in the 80s to where we are today in 2016,” Worsham said. “I was part of that progression; how we got where we are and the things that made it better, and maybe some things that weren’t as good.”

Through it all, good or bad, every tweak made to a part or adjustment made to the car, gives drag racing’s entrepreneurs invaluable data for both their business, and their pleasure.

“We have handled so many projects over the years. Some were good, some not so much, but it always taught us something,” Boninfante said. “We had a deal years ago with Penske and their IRL team to develop a slipper clutch for their cars. We worked on that project for close to two years, went through all of the R&D, built everything they needed. Once they got it all worked out, they submitted it for approval and it didn’t get approved.

“It let us down a little bit, but it was way out of the box. It didn’t affect what we did for them, because they were happy with it. That was a huge project for us, but that project, even though it didn’t pan out, it did help us learn more about those applications. Today, we are doing road racing clutches.

“Everything we have done; it helps us somewhere down the road. It is a unique relationship and a valuable chapter in the history of this company.”